Optimizing NMR Flow Cell Design for Enhanced Sensitivity in Reaction Monitoring and Drug Development

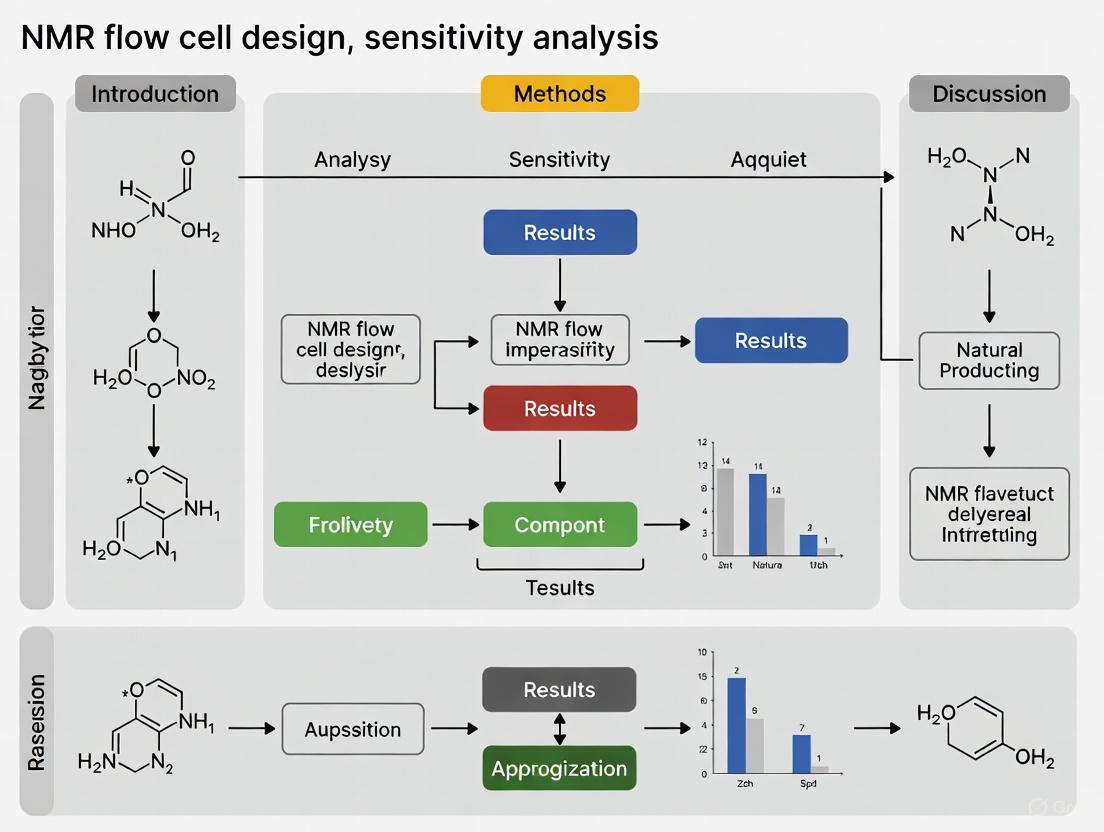

This article provides a comprehensive examination of Nuclear Magnetic Resonance (NMR) flow cell design and its critical impact on analytical sensitivity for researchers and drug development professionals.

Optimizing NMR Flow Cell Design for Enhanced Sensitivity in Reaction Monitoring and Drug Development

Abstract

This article provides a comprehensive examination of Nuclear Magnetic Resonance (NMR) flow cell design and its critical impact on analytical sensitivity for researchers and drug development professionals. It explores foundational principles of flow dynamics and their influence on signal quality, presents cutting-edge methodological applications in automated reaction monitoring and photochemistry, and offers practical troubleshooting guidance for optimizing cell geometry and flow profiles. The content further validates benchtop NMR performance against established techniques like HPLC-UV, demonstrating its growing capability for quantitative analysis in pharmaceutical and forensic applications. By synthesizing recent advances from computational fluid dynamics simulations to novel hardware integrations, this resource serves as an essential guide for implementing robust, high-sensitivity flow NMR across chemical and biomedical research workflows.

Fundamentals of NMR Flow Cell Design: How Geometry and Hydrodynamics Dictate Sensitivity

The Critical Relationship Between Flow Cell Design and NMR Signal Quality

Core Concepts: Flow and Signal Quality

This section explains the fundamental principles of how flow cell design impacts the quality of Nuclear Magnetic Resonance (NMR) data, which is critical for quantitative analysis.

The Premagnetization Challenge

In flow NMR spectroscopy, the nuclei in a sample must build up their magnetization, a process called premagnetization, as they travel through the premagnetization zone of the feed line before reaching the radio frequency (RF) coil where they are excited and measured [1]. A sufficiently long residence time in this zone is crucial for nuclei to reach their equilibrium magnetization.

Incomplete premagnetization occurs when the flow rate is too high, leaving insufficient time for this magnetization buildup. This leads to a reduction of signal intensity in the NMR spectrum [1]. When this happens, the observed peak intensity is no longer directly proportional to the concentration of the nuclei in the sample, making accurate quantification difficult or impossible [1]. This problem is particularly acute in compact medium-field NMR spectrometers because of their small magnet size and consequently small premagnetization volume [1] [2].

Residence Time Distribution and Flow Patterns

The flow pattern inside a cell is characterized by its Residence Time Distribution (RTD), which describes the range of times different fluid elements spend in the cell. Ideally, for minimal signal distortion and to represent the sample's true composition, the flow should be uniform [2].

The design of the flow cell, especially its geometry, inlet, and outlet, has a major influence on the internal flow pattern [2]. In practical applications, the flow is typically laminar. Complex geometries can lead to unwanted effects like flow channelling or regions of stagnated flow, which broaden the RTD and can cause mixing of separated compounds from an upstream chromatographic system [2]. The length of the flow cell is also an important parameter, as it must be sufficient to ensure a stable, laminar flow profile has developed within the sensitive region of the RF coil [2].

Table: Key Flow-Related Concepts and Their Impact on NMR Signal

| Concept | Description | Impact on NMR Signal |

|---|---|---|

| Premagnetization | The buildup of nuclear magnetization in the magnetic field before the sample enters the detection coil. | Incomplete premagnetization directly reduces signal intensity, hindering quantification [1]. |

| Longitudinal Relaxation Time (T₁) | The time constant for nuclei to recover their equilibrium magnetization after excitation. | Nuclei with longer T₁ times require longer residence times in the premagnetization zone to fully regain magnetization [1]. |

| Residence Time Distribution (RTD) | The distribution of times that different fluid elements spend in the flow cell. | A broad RTD can lead to varying degrees of premagnetization and signal loss, and can blur time-resolved data [2]. |

| Laminar Flow | A smooth, ordered flow regime. | The typical regime in NMR flow cells; its profile is determined by cell geometry and flow rate [2]. |

Troubleshooting FAQs

Signal Loss at High Flow Rates

Q: My NMR signal intensity drops significantly when I increase the flow rate. What is the cause and how can I mitigate it?

A: This is a classic symptom of incomplete premagnetization. At higher flow rates, the sample nuclei have less time to relax and build up magnetization in the magnetic field before reaching the detection coil. The signal reduction depends on the flow conditions and the longitudinal relaxation time (T₁) of the studied nucleus [1].

Mitigation Strategies:

- Reduce Flow Rate: The simplest solution is to lower the flow rate to allow for longer premagnetization times.

- Optimize Flow Cell Geometry: Use a flow cell with a longer or more effective premagnetization path. Some designs incorporate expansions or loopy paths to increase the residence time in the magnetic field [1].

- Apply a Signal Correction Model: For advanced applications, a correction factor can be calculated based on the T₁ times, flow rate, and flow cell geometry using Computational Fluid Dynamics (CFD) models, enabling quantitative work at higher flow rates without physical modifications [1].

Poor Chromatographic Resolution in On-line SEC-NMR

Q: When hyphenating Size Exclusion Chromatography (SEC) with NMR, my chromatographic peaks are broader than expected. Could the flow cell be responsible?

A: Yes. The design of the flow cell can significantly impact the observed chromatographic resolution. If the flow cell has a large internal volume or a geometry that causes significant back-mixing or broadening of the Residence Time Distribution (RTD), it will act as a mixing chamber and blur the separation achieved by the SEC columns [2].

Mitigation Strategies:

- Minimize Dead Volumes: Ensure the flow cell and all connecting capillaries are designed to minimize any areas of stagnant flow.

- Optimize Cell Geometry: A cell geometry that promotes a narrow RTD (closer to plug flow) is ideal. This often involves a straightforward path with an optimized inlet and outlet design to minimize turbulence or eddies [2].

- Match Cell Volume to System: The flow cell volume should be appropriately sized for the internal volume of your chromatographic system and the desired flow rates.

Inconsistent Quantification in Flowing Mixtures

Q: I am getting inconsistent quantitative results when analyzing flowing mixtures, even at moderate flow rates. Why?

A: In mixtures, different components can have vastly different T₁ relaxation times. In a flow system, these components may experience slightly different flow paths and residence times within the premagnetization zone due to the flow cell's RTD. Consequently, components with longer T₁ times might be disproportionately affected by the flow, leading to skewed intensity ratios in the NMR spectrum that do not reflect the true composition [1].

Mitigation Strategies:

- Ensure Complete Premagnetization: The most reliable method is to use a flow rate slow enough to ensure even the component with the longest T₁ is fully magnetized.

- Characterize T₁ Times: Know the T₁ relaxation times of all components in your mixture under the experimental conditions.

- Use Advanced Modeling: Implement a CFD-based transport model that can account for the specific flow cell geometry, magnetic field profile, and the different T₁ times of mixture components to calculate and apply accurate correction factors [1].

Experimental Protocols for Flow Cell Characterization

Protocol: Determining Residence Time Distribution via Tracer Experiments

1. Objective: To characterize the flow profile and identify dead volumes or mixing zones within a flow cell by measuring its Residence Time Distribution (RTD) [2].

2. Materials:

- NMR flow system with the flow cell to be tested.

- Deuterated solvent (e.g., D₂O).

- Tracer substances (e.g., ethanol, acetone, methanol), fully miscible with the solvent [2].

- Injection valve (e.g., a six-way valve).

3. Procedure: a. Set the system to a stable flow of the pure solvent at the desired rate. b. Inject a sharp pulse (or a step) of tracer substance into the solvent stream just upstream of the flow cell using the injection valve [2]. c. Continuously acquire ¹H NMR spectra with a high temporal resolution. d. Monitor the signal intensity of a characteristic proton peak from the tracer as it passes through the flow cell. e. Plot the intensity of this tracer signal versus time to obtain the RTD curve [2].

4. Data Interpretation: A narrow, symmetric RTD curve indicates a flow profile close to ideal plug flow with minimal mixing. A broad or asymmetric curve suggests significant dispersion, channelling, or the presence of dead volumes within the flow cell [2].

Protocol: Measuring Flow-Induced Signal Attenuation

1. Objective: To quantify the loss of NMR signal intensity as a function of flow rate for a given nucleus and flow cell.

2. Materials:

- NMR flow system.

- Standard sample with a known T₁ relaxation time (e.g., pure water or acetonitrile) [1].

3. Procedure: a. Place the standard sample in the flow system. b. Acquire a reference NMR spectrum with the flow stopped or at a very low flow rate where signal attenuation is negligible. c. Incrementally increase the flow rate, acquiring a series of NMR spectra under identical experimental parameters (e.g., number of scans, receiver gain). d. For each spectrum, measure the signal intensity of a specific peak.

4. Data Analysis: a. Plot the relative signal intensity (signal at flow rate / reference signal) against the flow rate. b. The curve will show a decay, which is characteristic for the combination of your sample's T₁ and the flow cell's premagnetization efficiency [1]. c. This data can be used to determine the maximum flow rate for quantitative work or to calibrate a model for signal correction.

Flow Signal Attenuation Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table: Essential Materials for NMR Flow Cell Experiments

| Item | Function / Application |

|---|---|

| ACN/D₂O Mixtures | Model fluids with non-linear T₁ relaxation behavior for validating signal correction models and testing system performance under demanding conditions [1]. |

| Tracer Substances (e.g., Ethanol, Acetone) | Used in pulse-tracer experiments to characterize the Residence Time Distribution (RTD) of a flow cell [2]. |

| Deuterated Solvent (e.g., CDCl₃, D₂O) | Provides a lock signal for the NMR spectrometer. Essential for maintaining field stability during long flow experiments, though often cost-prohibitive for continuous use as a mobile phase in preparative chromatography [3]. |

| Polymer Standards (e.g., PS, PMMA) | Used for testing and optimizing hyphenated systems like SEC-NMR, allowing correlation of molar mass with chemical composition from NMR data [3]. |

| High-Field NMR Flow Probe (e.g., 95 µl active volume) | A standard tool for initial method development with high sensitivity, often used before transferring methods to more compact benchtop NMR systems [2]. |

Advanced Modeling and Design

For predictive design and quantitative correction, Computational Fluid Dynamics (CFD) is a powerful tool. It involves solving the Navier-Stokes equations to predict the velocity field within a given flow cell geometry [1]. This flow field can be coupled with a transport model based on the Bloch equations to simulate the magnetization of nuclei as they move through the premagnetization zone and into the detection region [1].

This augmented CFD model can predict the component- and flow-rate-dependent signal reduction, making time-consuming calibration measurements for each new condition obsolete. With this approach, quantitative NMR measurements at high flow rates become possible by calculating correction factors based solely on simple static T₁ measurements and the simulated flow behavior [1].

CFD Modeling for Flow NMR

Frequently Asked Questions (FAQs)

FAQ 1: Why is understanding the flow regime (laminar vs. turbulent) critical for my NMR flow cell experiments?

The flow regime within your NMR flow cell directly impacts the quality of your data and the validity of your analysis. Laminar flow provides a predictable, smooth velocity profile, which is essential for achieving high-resolution spectra and for accurate quantitative analysis, such as determining reaction kinetics in flow synthesis [4]. Turbulent flow, while sometimes desirable for enhancing mixing or heat transfer, can lead to broadened spectral lines and increased noise due to its chaotic nature [5]. Furthermore, the flow regime is a primary factor determining the Residence Time Distribution (RTD), which characterizes mixing efficiency and reaction progress in your system [6] [2].

FAQ 2: How can I determine if the flow in my system is laminar or turbulent?

You can predict the flow regime by calculating the Reynolds number (Re), a dimensionless parameter. The Reynolds number represents the ratio of inertial forces to viscous forces in a fluid [5] [7]. The generally accepted thresholds for flow in a pipe are [7] [8]:

- Re < 2000: Laminar flow

- 2000 < Re < 3500: Transitional flow

- Re > 3500: Turbulent flow

The Reynolds number is calculated as: Re = ρVD / μ Where:

- ρ = fluid density (kg/m³)

- V = average fluid velocity (m/s)

- D = characteristic dimension, typically the hydraulic diameter of the pipe or flow cell (m)

- μ = dynamic viscosity of the fluid (Pa·s) [5] [8]

FAQ 3: What is Residence Time Distribution (RTD) and why is it important for my multichannel flow reactor?

Residence Time Distribution (RTD) is a measure of the time that fluid elements spend inside a flow system [6]. It is a frequently used tool for the internal characterization of process equipment via simple tracer tests [6]. In multichannel systems, such as numbered-up reactors, a non-uniform RTD can reveal maldistribution of fluid between channels, which is a key issue that can degrade global performance [6]. Uneven flow can lead to unbalanced reagent composition, different reaction kinetics in different channels, and heterogeneous final products, making RTD a vital diagnostic tool [6].

FAQ 4: I am observing poor spectral resolution in my flow NMR experiments. What could be the cause?

Poor resolution can often be traced to issues with flow conditions or system setup. Key areas to investigate are:

- Flow Regime: Ensure your flow is in the laminar regime (Re < 2000) to avoid chaotic mixing and signal instability [5] [7].

- Air Bubbles: The presence of air bubbles in or near the RF coil can significantly distort spectral quality. Using a segmented-flow approach with fluorinated oil can help isolate samples and prevent this issue [9].

- Shimming: Inadequate shimming of the magnetic field will result in poor resolution. Ensure your sample is homogeneous and free of air bubbles or insoluble substances, and use automated shimming routines to optimize the magnetic field homogeneity [10].

- Flow Cell Design: The geometry of the inlet and outlet of the flow cell has a major influence on the flow pattern. Abrupt changes can lead to flow channeling or dead volumes, disrupting the laminar profile and broadening the RTD [2].

Troubleshooting Guides

Troubleshooting Guide 1: Diagnosing and Addressing Non-Ideal Flow Regimes

| Symptom | Possible Cause | Diagnostic Experiment | Solution |

|---|---|---|---|

| Broadened NMR peaks, noisy baseline | Turbulent flow in the detection cell | Calculate the Reynolds number (Re) for your flow conditions. | Reduce the flow rate or use a fluid with higher viscosity to lower the Reynolds number into the laminar regime. |

| Unreliable reaction kinetics data | Transitional flow regime (neither fully laminar nor turbulent) | Calculate the Reynolds number to confirm it is between 2000 and 3500. | Adjust flow rate or viscosity to achieve a definitively low (laminar) or high (turbulent) Re, depending on experimental needs. |

| Inefficient mixing in a T-junction | Low Reynolds number (laminar flow), relying only on slow diffusion | Visualize mixing with a dye tracer or measure RTD. | Incorporate a static mixer element or design a mixing zone that induces chaotic advection to enhance mixing while maintaining controlled flow. |

Troubleshooting Guide 2: Diagnosing Issues with Residence Time Distribution (RTD)

| Symptom | Possible Cause | Diagnostic Experiment | Solution |

|---|---|---|---|

| RTD curve is broader than expected for a single channel. | Dead volumes in the flow path (e.g., in junctions, oversized cells). | Perform a tracer test and compare the output RTD to a model prediction for your system geometry. | Redesign the flow path to minimize unswept volumes. Use Computational Fluid Dynamics (CFD) simulation to identify problem areas [2]. |

| Multiple peaks in the RTD curve of a multichannel device. | Severe flow maldistribution between parallel channels. | Conduct a non-intrusive RTD measurement on the entire device [6]. | Redesign the fluid distributor/collector manifolds to ensure equal flow resistance to each channel. A tree-like structure is often effective [6]. |

| RTD changes over time in a single experiment. | Partial blockage or corrosion in the flow path, altering flow resistance. | Monitor system pressure. Repeat RTD measurements at different times. | Implement a filtration step upstream. Use materials resistant to corrosion or fouling, such as fluorinated polymers [6] [9]. |

Experimental Protocols

Protocol 1: Determining Flow Regime Using Reynolds Number Calculation

Objective: To quantitatively determine whether the flow in your NMR flow cell is laminar, transitional, or turbulent.

Materials:

- The fluid to be used in your experiment.

- Data on fluid properties (density, viscosity) at operating temperature.

- Dimensions of the flow cell (internal diameter).

- Syringe pump or HPLC pump with known flow rate.

Methodology:

- Determine Fluid Properties: Obtain the dynamic viscosity (μ) and density (ρ) of your fluid at the temperature of your experiment. These values can often be found in chemical databases or measured with a viscometer and densitometer.

- Characterize Flow Cell Geometry: Measure the internal diameter (D) of your flow cell. This is the characteristic dimension.

- Set Flow Rate: Set your pump to the desired volumetric flow rate (Q).

- Calculate Average Velocity (V): Calculate the average fluid velocity using the equation: V = Q / A, where A is the cross-sectional area of the flow cell (A = πD²/4 for a circular tube).

- Calculate Reynolds Number (Re): Use the formula: Re = ρVD / μ.

- Interpret the Result:

Protocol 2: Characterizing System Performance via Residence Time Distribution (RTD)

Objective: To experimentally measure the Residence Time Distribution of your flow system to identify dead volumes, channeling, or maldistribution.

Materials:

- Your flow system (reactor, multichannel device, etc.).

- A non-reactive tracer (e.g., a dye, salt, or a compound detectable by UV-Vis or conductivity).

- A detector (e.g., UV-Vis spectrophotometer, conductivity meter, or fast camera for visualization) placed at the system outlet [6].

- A data acquisition system to record the detector's signal over time.

Methodology:

- System Stabilization: Run your system with the main process fluid at the desired steady-state flow rate.

- Tracer Injection: Quickly inject a small pulse of tracer into the fluid stream at the system inlet. The injection should be as instantaneous as possible.

- Data Collection: Record the concentration of the tracer at the outlet as a function of time, C(t). This is the E(t) curve.

- Data Analysis: The mean of the E(t) curve represents the average residence time in your system. The shape and breadth of the curve provide diagnostic information:

- A narrow, symmetric peak indicates flow behavior close to an ideal plug-flow reactor (PFR), with minimal axial dispersion.

- A broad, asymmetric peak with tailing suggests significant axial dispersion or the presence of dead volumes [6] [2].

- For a multichannel device, a broadened or multi-modal RTD is a direct indicator of uneven flowrate distribution among the channels [6].

Data Presentation

Table 1: Characteristics of Laminar and Turbulent Flow Regimes

| Parameter | Laminar Flow | Turbulent Flow |

|---|---|---|

| Reynolds Number (Re) | < 2000 [7] [8] | > 3500 [7] [8] |

| Flow Pattern | Smooth, orderly, parallel layers [5] [8] | Chaotic, irregular, with eddies and swirls [5] [7] |

| Velocity Profile | Parabolic (in pipes), with maximum velocity at the center [8] | Fairly flat across the pipe, then drops off sharply near the wall [8] |

| Mixing Mechanism | Molecular diffusion (slow, perpendicular to flow) [5] | Convective eddies (rapid, three-dimensional) [5] |

| Impact on NMR | High spectral resolution; predictable environment [4] | Potential for signal noise and broadened lines [5] |

| Pressure Drop | Proportional to flow rate [5] | Proportional to flow rate raised to a power ~1.8 [5] |

| Primary Dependence | Viscous forces dominate [5] | Inertial forces dominate [5] |

Mandatory Visualization

Experimental RTD Workflow

Flow Regime Characteristics

The Scientist's Toolkit

Key Research Reagent Solutions for Flow NMR & RTD Experiments

| Item | Function | Application Note |

|---|---|---|

| Fluorinated Oil (e.g., FC-72) | Acts as an immiscible carrier phase in segmented-flow analysis (SFA). It minimizes sample dispersion, reduces carryover, and prevents air bubbles from entering the detector [9]. | Its magnetic susceptibility is similar to copper, allowing for a good lineshape without excessive sample overfill [9]. |

| Deuterated Solvent (D₂O, etc.) | Provides a signal for the NMR spectrometer's lock system, ensuring magnetic field stability during prolonged experiments. | Can be expensive. Solvent suppression pulse sequences (e.g., WET) can be used in flow NMR to reduce or eliminate the need for deuterated solvents in the sample itself [4]. |

| Chemical Tracer (e.g., dye, salt, carbon ink) | A non-reactive compound used to trace the path of fluid through a system. Its concentration at the outlet is measured to determine the RTD [6]. | For systems with very short residence times (down to 1 second), a fast detection method like a high-speed camera is required [6]. |

| PCTFE (Polychlorotrifluoroethylene) Flow Cell | The main body of the flow cell, positioned within the NMR detector. PCTFE is a fluoropolymer suitable for a wide range of chemicals and facilitates a smooth flow path [9]. | A well-designed flow cell has a larger inner diameter in the detection zone and conical transitions to minimize dead volumes and promote laminar flow [2] [9]. |

| PEEK Tubing | Polyether ether ketone tubing is commonly used for fluidic connections due to its high strength and compatibility with NMR systems [4]. | Note that PEEK absorbs DMSO and methanol and is not compatible with strong acids. Its poor turn radius requires careful system layout [4]. |

Impact of Inlet/Outlet Geometry and Cell Length on Mixing and Stagnation

Troubleshooting Guide: Flow Cell Performance Issues

FAQ: How do inlet and outlet design features influence flow within an NMR flow cell?

The geometry of the inlet and outlet is a critical factor that determines the flow profile inside the cell. Abrupt changes in diameter, such as sharp expansions or contractions, disrupt laminar flow and create problematic flow patterns. These include recirculation zones (eddies) and regions of stagnant flow, where fluid remains trapped and is only slowly exchanged. Such anomalies lead to increased residence time distribution (RTD), which causes sample dispersion, cross-contamination between consecutive samples, and makes quantitative analysis unreliable [2] [11].

Conversely, a design that incorporates gradual, tapered transitions at the inlet and outlet guides the fluid smoothly into and out of the detection volume. This design minimizes radial velocity components and prevents the formation of recirculation zones, thereby promoting a more uniform, laminar flow profile that closely approximates plug flow. This is essential for maintaining the integrity of separated samples from techniques like chromatography and for obtaining accurate, quantitative NMR data [2] [11].

FAQ: What is the effect of flow cell length on mixing and spectral quality?

The length of the flow cell has a direct and competing impact on both the hydrodynamic and spectroscopic performance of the system.

- From a flow dynamics perspective, a longer flow path allows more time for a perturbed velocity profile (e.g., from a inlet jet) to re-develop into a stable, laminar parabolic profile before the fluid reaches the sensitive detection region. This helps minimize mixing and dispersion [2].

- From an NMR sensitivity and resolution perspective, the flow cell length must be matched to the length of the NMR probe's radiofrequency (RF) coil's sensitive region. In Medium-Resolution NMR (MR-NMR) systems, which have a relatively small zone of magnetic field homogeneity, an excessively long cell will contain sample outside this homogeneous region. The signal from these regions contributes noise and broadens spectral lines, degrading resolution. Therefore, the cell must be long enough to ensure a stable flow profile but short enough to fit within the magnet's homogeneous region for optimal spectral linewidth [2].

The table below summarizes the effects of different geometric features on flow cell performance.

Table 1: Impact of Flow Cell Geometry on Performance

| Geometric Feature | Problematic Design | Optimal Design | Primary Impact on Performance |

|---|---|---|---|

| Inlet/Outlet Transition | Abrupt, sharp expansion/contraction [11] | Gradual, tapered transition (Normalized transition length ≥ 12) [11] | Prevents recirculation zones and stagnant flow; reduces sample dispersion and carryover. |

| Flow Cell Length | Too short for inlet flow profile to develop; too long for the magnet's homogeneous region [2] | Matched to the length required for laminar flow development within the magnet's homogeneous zone [2] | Balances stable laminar flow (minimized RTD) with optimal NMR spectral resolution and signal-to-noise ratio. |

| Normalized Transition Length | A value of 0 (abrupt change) [11] | A value of 12 (gradual change) [11] | A longer normalized transition length directly correlates with the elimination of recirculation vortices and radical velocities. |

FAQ: How can I experimentally diagnose poor flow profiles in my setup?

Two powerful methods for characterizing flow profiles are Residence Time Distribution (RTD) analysis and direct velocity imaging.

Protocol 1: Residence Time Distribution (RTD) via Tracer Pulse NMR This method provides an integral view of mixing and flow characteristics by measuring how long different fluid elements reside in the cell [2].

- Setup: Integrate the flow cell into your FlowNMR system with a bypass loop from the main reactor. Use a multi-way valve close to the flow cell inlet for tracer injection.

- Tracer Injection: Inject a small, distinct pulse of a miscible tracer substance (e.g., ethanol, acetone, or methanol in water) into the flowing stream via the injection valve [2].

- NMR Monitoring: Continuously acquire 1H NMR spectra at a high temporal resolution immediately after the injection.

- Data Analysis: Plot the concentration of the tracer (determined from NMR signal intensity) against time. A narrow, symmetric RTD curve indicates flow that approximates plug flow with minimal back-mixing. A broad, asymmetric curve with tailing indicates significant channeling, stagnant zones, or back-mixing [2].

Protocol 2: Direct Flow Visualization via Magnetic Resonance Imaging (MRI) Velocimetry This method directly maps the velocity field inside the flow cell, allowing for visual identification of recirculation zones and stagnant areas [2] [11].

- Setup: Place the flow cell in the NMR spectrometer or MRI system.

- Flow Conditioning: Use a syringe pump to establish a steady, laminar flow of the fluid of interest at the desired rate.

- Velocity Encoding: Implement a phase-contrast MR imaging sequence. This sequence encodes the velocity of spinning nuclei into the phase of the NMR signal.

- Image Acquisition: Acquire images in multiple spatial and velocity encoding directions to reconstruct 2D or 3D velocity vector maps.

- Data Analysis: The resulting velocity maps will visually show the flow streamlines, allowing for direct identification of regions with recirculation, stagnation, or non-ideal radial velocities [11]. This data can also be used to validate Computational Fluid Dynamics (CFD) simulations of your cell design [2].

Experimental Protocols for Flow Cell Characterization

Detailed Methodology: Coupling CFD and NMR for Flow Profile Optimization

This protocol outlines a combined computational and experimental approach to rigorously characterize and optimize flow cell design.

Aim: To validate a new flow cell geometry by comparing simulated flow patterns from Computational Fluid Dynamics (CFD) with experimental data from MR velocimetry.

Materials:

- CAD model of the proposed flow cell geometry.

- CFD software (e.g., ANSYS Fluent).

- NMR spectrometer with imaging capabilities.

- Fabricated flow cell prototype.

- Syringe pump and tubing.

Procedure:

- CFD Simulation:

- Import the flow cell geometry into the CFD software.

- Mesh the geometry, ensuring higher mesh density in regions of expected high-velocity gradients (e.g., near inlets/outlets and walls).

- Define boundary conditions: Set the inlet to a defined flow rate (e.g., 0.1 to 10 mL/min) and the outlet to zero pressure.

- Solve the Navier-Stokes equations for incompressible, steady-state laminar flow to obtain the velocity field [11].

- MR Velocimetry Experiment:

- Connect the flow cell prototype to the syringe pump and introduce the working fluid.

- Position the cell in the center of the NMR magnet.

- Run a phase-contrast MRI sequence under identical flow conditions used in the CFD simulation.

- Measure the velocity fields in multiple dimensions to create a 3D map of the flow [11].

- Validation and Analysis:

- Directly compare the velocity fields obtained from CFD and MRI.

- Quantitatively assess the agreement by comparing velocity profiles along the central axis and at various cross-sections.

- Use the validated CFD model to perform virtual experiments and optimize the geometry before fabricating a new prototype [2].

Flow Dynamics Visualization

The following diagram illustrates the relationship between flow cell geometry and the resulting internal flow patterns, which directly impact performance.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for NMR Flow Cell Fabrication and Testing

| Item Name | Function / Rationale | Key Considerations |

|---|---|---|

| Quartz Capillary | Primary material for fabricating high-precision flow cells due to its uniformity, magnetic susceptibility matching, and mechanical strength [12] [4]. | Excellent for high-field NMR; requires hydrofluoric acid for complex etching [11]. |

| PCTFE (Polychlorotrifluoroethylene) | Polymer for novel flow cell fabrication; offers good machinability and compatibility with a segmented flow analysis platform using fluorinated oils [9]. | Can be thermally compression molded for a smooth inner surface to optimize flow [9]. |

| PEEK Tubing & Fittings | Standard for fluidic connections due to high pressure rating and strength. Common in commercial setups [12] [13]. | Not compatible with strong acids; can absorb DMSO and methanol [12] [13]. |

| FC-72 Fluorinated Oil | Carrier fluid in Segmented-Flow Analysis (SFA) to separate sample segments. Its magnetic susceptibility is similar to copper, improving spectral line shape [9]. | Extraordinarily non-polar, preventing sample/oil partitioning; forms a protective film in fluoropolymer tubing [9]. |

| Deuterated Solvent (e.g., D₂O) | Standard solvent for NMR experiments to provide a field-frequency lock signal, eliminating the need for repeated shimming in flow systems [3]. | High cost can be prohibitive for large-scale screening; may contain protonated impurities [3]. |

| Protonated Solvent with Suppression | Cost-effective alternative to deuterated solvents. Requires pulse sequences like WET for effective solvent signal suppression [14] [12]. | Essential for high-throughput analysis with benchtop NMR; effectiveness of suppression is critical for analyte detection [14]. |

Computational Fluid Dynamics (CFD) and NMR Imaging for Flow Characterization

Frequently Asked Questions (FAQs)

FAQ 1: Why is the design of the flow cell critical for on-line NMR in process analytics?

The flow cell is a non-negligible part of the total system volume and its geometry directly influences the flow profile, which in turn affects the residence time distribution (RTD) and mixing effects [2]. An optimal design ensures that the detected signal accurately reflects the actual composition of the sample from the reactor. Imperfections in design can lead to issues like flow channelling, regions of stagnated flow, or back-mixing, which compromise the representativeness of the measurement and can broaden NMR spectral lines [2] [11]. The ultimate goals are to minimize residence time and achieve a flow profile that closely resembles plug flow within the bypass.

FAQ 2: What specific flow cell geometry factors should I consider to minimize peak dispersion?

The geometry of the inlet and outlet, specifically the normalized transition length (the ratio of the transition region length to the capillary inner diameter), is a primary factor [11]. Numerical simulations and Magnetic Resonance (MR) microimaging have shown that an abrupt expansion and contraction (normalized transition length of 0) creates complex flow patterns, including areas of weak recirculation and strong radial velocities, which degrade separation efficiency [11]. A design with a more gradual expansion and contraction is necessary to avoid these issues and ensure a smoother, more predictable laminar flow profile in the detection region.

FAQ 3: How can I validate the flow patterns predicted by my CFD simulations in an actual flow cell?

Magnetic Resonance (MR) microimaging is a powerful experimental technique for directly measuring velocity fields inside flow cells and is well-suited for validating CFD simulations [11]. Methods like pulsed-field gradient spin–echo (PGSE) experiments can encode both flow velocity and diffusion, providing detailed three-dimensional velocity maps [11]. Studies have confirmed good agreement between the velocity fields measured by MR microimaging and those predicted by CFD simulations, making this a robust approach for experimental verification [11].

FAQ 4: My in-cell NMR spectra of proteins show broadened peaks. What are the primary causes and solutions?

In-cell NMR peak broadening is predominantly caused by quinary interactions (transient, non-specific interactions with other macromolecular components in the cytosol) and increased viscosity, which increase the apparent molecular weight and reduce the tumbling rate of the protein [15]. This leads to a reduced transverse relaxation time (T2) and broader crosspeaks. To alleviate this, advanced pulse sequences such as CRINEPT (Cross Relaxation-Enhanced Polarization Transfer) and TROSY (Transverse Relaxation-Optimized Spectroscopy) should be employed. These techniques are specifically designed to increase sensitivity and resolution for large molecular species with long rotational correlation times (τc) [15].

Troubleshooting Guides

Troubleshooting Flow-Related NMR Spectral Broadening

| Symptom | Possible Cause | Solution | Preventive Measure |

|---|---|---|---|

| Broadened NMR peaks during flow. | Very high flow rate reducing residence time in the detection cell [11]. | Reduce the flow rate to increase the residence time (τ). | Characterize the relationship between flow rate and linewidth for your specific flow cell [11]. |

| Complex flow patterns (e.g., recirculation, channelling) due to poor flow cell geometry [2]. | Characterize flow profile using CFD and NMR imaging; redesign flow cell with gradual inlets/outlets. | Optimize flow cell design using CFD simulations prior to fabrication, focusing on inlet/outlet geometry [11]. | |

| Inaccurate residence time distribution (RTD). | Stagnated flow regions or dead volumes within the flow cell or its connections [2]. | Perform a pulse-tracer experiment with NMR to identify dead volume locations; check and optimize all tubing junctions. | Minimize the total volume of the bypass system and use smooth, well-connected tubing with minimal internal diameter changes. |

| Unstable NMR signal or poor shim in flow mode. | Air bubbles trapped in the flow cell or tubing. | Implement a bubble trap in the flow line; flush system thoroughly with degassed solvent. | Ensure all connections are tight and use a back-pressure regulator after the detection cell. |

Troubleshooting CFD Simulation of Flow Cells

| Symptom | Possible Cause | Solution |

|---|---|---|

| Simulation fails to converge. | Overly complex mesh or inappropriate boundary conditions. | Simplify the mesh in regions of low interest; re-check and apply fully developed laminar flow boundary conditions at inlet [11]. |

| Simulation results show unrealistic turbulence at low flow rates. | Incorrect model for fluid flow (e.g., using a turbulent model for laminar flow). | Confirm the Reynolds number for your system is within the laminar flow regime and select a laminar flow model. |

| Discrepancy between CFD velocity fields and MR microimaging data. | Inaccurate geometry representation in the simulation or insufficient mesh resolution. | Ensure the CAD model of the flow cell matches the physical device exactly; increase mesh density in areas of high velocity gradient [11]. |

Experimental Protocols

Protocol: Characterizing Residence Time Distribution (RTD) via Pulse-Tracer NMR

1. Purpose: To gain integral information about the flow properties in a bypass system, including the flow cell, by determining the Residence Time Distribution (RTD). This helps identify mixing effects, wall adhesion, and regions of stagnated flow [2].

2. Materials:

- NMR flow probe with integrated flow cell.

- Syringe or HPLC pump for precise fluid delivery.

- Multi-port injection valve.

- Miscible tracer substances (e.g., ethanol, acetone, methanol in water) [2].

- Deuterated solvent for locking (if required by the NMR system).

3. Procedure: 1. Set up the flow system with the pump, injection valve, and NMR flow cell. 2. Continuously pump the main solvent through the system at the desired flow rate (e.g., 0.1 - 10 mL/min) [2]. 3. Using the injection valve, inject a small, sharp pulse of a tracer substance as close as possible to the flow cell inlet. 4. Immediately after injection, start acquiring a rapid series of 1H NMR spectra. 5. Monitor the NMR signal of the tracer as it passes through the detection volume. The signal intensity over time represents the residence time distribution for that flow condition. 6. Repeat the sequence with different tracers or at different flow rates to build a comprehensive picture [2].

4. Data Analysis: The time-dependent concentration (from NMR signal intensity) of the tracer at the outlet is the RTD function. A narrow, Gaussian-like distribution indicates flow close to ideal plug flow, while a distribution with tailing suggests significant back-mixing or dead volume.

Protocol: Validating CFD Flow Patterns with MR Microimaging

1. Purpose: To experimentally measure the velocity fields inside a flow cell for direct comparison and validation of Computational Fluid Dynamics (CFD) simulations [11].

2. Materials:

- NMR spectrometer equipped with imaging gradients.

- Custom-built or commercial flow cell.

- Syringe pump.

- Fluid for testing (e.g., water).

3. Procedure: 1. Mount the flow cell within the RF coil inside the magnet. 2. Connect the flow cell to the syringe pump and flow the test fluid at a steady, known rate. 3. Implement a pulsed-field gradient spin–echo (PGSE) based flow imaging sequence. This sequence is sensitive to both molecular displacement (flow) and diffusion [11]. 4. Acquire images and phase data that encode velocity information in different spatial directions. 5. Process the data to reconstruct 2D or 3D velocity maps showing axial and radial velocity components within the flow cell.

4. Data Analysis: Compare the measured velocity fields from MR microimaging with the velocity fields predicted by your CFD simulation. Good agreement between experiment and simulation confirms the accuracy of the computational model and provides confidence in its predictive capabilities for further design optimization [11].

Research Reagent Solutions

The table below lists key materials and computational tools used in the featured experiments for CFD and NMR flow characterization.

| Item Name | Function/Application | Specific Example/Note |

|---|---|---|

| Quartz Capillary | Material for fabricating precision flow cells due to its uniformity, purity, and excellent mechanical/electrical properties [4]. | Used with hydrofluoric acid etching to create flow cells with gradual transitions [11]. |

| PEEK Tubing | Poly-ether-ketone; commonly used for tubing connections in flow NMR systems due to its strength [4]. | Note: Absorbs DMSO and CH3OH, not compatible with strong acids, and has a poor turn radius [4]. |

| ANSYS Fluent | General-purpose Finite Element Method (FEM) software for performing Computational Fluid Dynamics (CFD) simulations [16]. | Used to simulate fluid flow, temperature gradients, and optimize sensor placement in flow systems [16]. |

| CRINEPT-TROSY Pulse Sequence | Advanced NMR pulse sequence to improve sensitivity and resolution for large molecular weight species in viscous environments (e.g., in-cell NMR) [15]. | Combines CRINEPT for efficient polarization transfer and TROSY to suppress transverse relaxation [15]. |

Workflow and Signaling Diagrams

Flow Cell Optimization Workflow

The following diagram illustrates the integrated methodology for designing and validating an optimized NMR flow cell, combining computational and experimental approaches.

Flow Characterization Signaling Pathway

This diagram outlines the logical relationship between a flow cell's physical design, the resulting fluid dynamics, the observed NMR phenomena, and the final experimental outcomes.

Special Design Considerations for Benchtop vs. High-Field NMR Systems

Troubleshooting Guides

Flow Cell and By-Pass System Issues

Problem: Poor spectral resolution or distorted signals in on-line process monitoring.

Flow cells in by-pass systems require careful design to minimize residence time and avoid mixing effects that distort the analytical signal. The design is particularly critical for Medium-Resolution NMR (MR-NMR) due to its smaller homogeneous magnetic field region. [2]

- Cause: Non-ideal flow patterns within the flow cell, such as channelling, back-mixing, or regions of stagnated flow, can alter the residence time distribution (RTD). This makes the detected signal unrepresentative of the actual process stream composition. [2]

- Solution:

- Optimize Flow Cell Geometry: Use Computational Fluid Dynamics (CFD) simulations to model and optimize the inlet, outlet, and length of the flow cell to achieve a laminar flow profile in the sensitive region. [2]

- Minimize Cell Volume: Reduce the flow cell volume to decrease the RTD. This is especially important for benchtop MR-NMR systems where the magnet's homogeneous region is small. [2]

- Experimental Characterization: Characterize the flow pattern experimentally using

1H NMR spectroscopyorNMR imaging (MRI)to perform pulse-tracer or step-tracer experiments. This validates the RTD and identifies issues like wall adhesion. [2]

Problem: Reduced sensitivity when hyphenating Benchtop NMR with Separation Techniques like SEC.

Coupling benchtop NMR (e.g., 62 MHz) as a detector for Size Exclusion Chromatography (SEC) presents sensitivity challenges due to low analyte concentration post-separation and the intrinsic lower sensitivity of low-field instruments. [3]

- Cause: The signal-to-noise (S/N) ratio in NMR scales approximately with the magnetic field strength (B₀) raised to the power of ~1.5. Furthermore, SEC requires dilute solutions, resulting in a high solvent-to-analyte ratio. [3]

- Solution:

- Custom Flow Cells: Design and use custom, optimized flow cells that maximize the filling factor within the instrument's limited homogeneous region. [3]

- Solvent Signal Suppression: Employ advanced pulse sequences with frequency-selective pulses to suppress the large signal from protonated solvents, which are typically used for cost reasons instead of deuterated solvents. [3]

- System Optimization: Fully optimize the entire hyphenated setup, including sample concentration, chromatographic columns, flow rates, and data evaluation workflows to maximize the S/N. [3]

General NMR Operation Issues

Problem: The sample won't spin.

Sample rotation is essential for high-field NMR to enhance resolution by averaging out field inhomogeneities. [17]

- Cause: The most common cause is a dirty probe. Dust, dirt, or moisture on the stator surface prevents the spinner from lifting and rotating properly. [17]

- Solution:

- Remove the sample.

- Inspect the probe interior with a flashlight, locating the stator and its three small air holes.

- Use a probe cleaning kit (an aluminum rod with cotton swabs). Soak a swab in isopropanol or acetone, insert it into the probe, and firmly polish the 45° surface of the stator, focusing on the machined holes.

- Repeat with clean swabs until no more discoloration (oxidation) is seen.

- Clean the spinner itself with isopropanol and re-insert the sample. [17]

Problem: The spectrometer does not lock.

The lock system stabilizes the magnetic field for long-term experiments. [18]

- Cause: Incorrect sample preparation (e.g., insufficient deuterated solvent) or incorrect lock parameters. [18]

- Solution:

- Ensure the sample has enough liquid and contains a sufficient amount of deuterated solvent.

- Type

iiin the TopSpin command line to re-initialize the interface. Repeat if errors occur. [18] [19] - In the BSMS Control window (

bsmsdisp), go to the LOCK tab. - If the lock signal is absent or not centered, use

Field -> Adjust Field. - If the signal is too big/small, use

Lock gain -> Adjust Gain. - If the signal is not symmetrical, use

Phase -> Adjust Phase. - Once adjusted, click 'On' to engage the lock. [18]

Problem: Poor shimming results, leading to broad peaks.

Shimming maximizes the homogeneity of the magnetic field across the sample. [10]

- Cause: Incorrect sample volume, air bubbles, insoluble substances, poor quality NMR tube, or not starting from a good shim file. [10]

- Solution:

- Ensure you have the required sample volume and that the sample is homogeneous.

- Type

rshand select a recent, high-quality 3D shim file for your specific probe (e.g.,TS3D_XXXXXX). [10] [19] - Run

topshim. If you get errors like "not enough valid points" or "too many points lost during fit", trytopshim convcompto compensate for convection currents, especially for non-viscous solvents. [18] - For persistent issues, manual optimization of

X,Y,XZ, andYZshims may be necessary, re-optimizingZafter adjusting each one. [10]

Frequently Asked Questions (FAQs)

Q1: What are the fundamental sensitivity trade-offs between benchtop and high-field NMR? The primary trade-off is between sensitivity/resolution and accessibility/cost. High-field NMR (e.g., 400-900 MHz) offers superior sensitivity (S/N ∝ B₀^1.5) and spectral dispersion, which is crucial for complex molecules. [3] [20] Benchtop NMR (typically 60-100 MHz) provides lower resolution and sensitivity but is more affordable, requires no cryogens, and can be integrated directly into workflows, such as in a fume hood or for on-line process monitoring. [20] For many routine analyses and hyphenated techniques, the sensitivity of modern benchtop systems is sufficient when the entire system is optimized. [3]

Q2: Why is flow cell design more critical for benchtop NMR in process analytics? Benchtop NMR systems have a much smaller region of highly homogeneous magnetic field (B₀). Therefore, the flow cell must not only minimize residence time to be representative but also restrict its active volume to this small, homogeneous region to maintain spectral resolution. In high-field systems, the longer sample cells typically ensure a laminar flow profile in the sensitive volume, whereas in benchtop systems, even small geometric imperfections can significantly distort the flow profile and the measured signal. [2]

Q3: Can I perform advanced experiments like kinetics or electrochemistry on a benchtop NMR? Yes. The principles of specialized NMR applications are transferable. For example, the design of electrochemical (EC)-NMR cells requires careful management of magnetic field distortions (B₀ and B₁) caused by introducing conductive electrodes. This involves simulations and workflows that are applicable regardless of field strength. [21] Similarly, rapid-injection (RI-NMR) and LED-NMR setups for kinetic studies have been successfully implemented on high-field systems and demonstrate the type of experimental designs that can be adapted for benchtop use. [22]

Q4: My sample is in a non-deuterated solvent. Can I still shim the magnet? Yes. While using a deuterated solvent for the lock system is standard, you can shim on the proton signal of your analyte.

- Run a 1D proton experiment with a default shim set (

rsh). - Use the command

gsto run the experiment in "live" mode. - In the BSMS window, turn the LOCK off and go to the SHIM tab.

- Adjust the shims (e.g., Z, Z1, X, Y) to maximize the amplitude and improve the shape of a prominent proton signal from your sample. [18]

Alternatively, use the command

topshim lockoff 1h o1p=x.xx, wherex.xxis the ppm value of your reference proton signal. [18]

Table 1: Key Flow Cell and Sensitivity Parameters in NMR Hyphenation

| Parameter | High-Field NMR (e.g., 400-900 MHz) | Benchtop NMR (e.g., 62-100 MHz) | Considerations and References |

|---|---|---|---|

| Typical Flow Cell Volume | ~95 μL (for a standard flow probe) [2] | Optimized to be significantly smaller to match the homogeneous region [2] [3] | Larger volumes increase residence time; benchtop requires a compromise between volume and homogeneity. [2] |

| Typical Flow Rates (LC-NMR) | Applicable over a wide range | 0.1 to 10 mL/min (optimized for specific setup) [2] [3] | Flow rate must be optimized with cell geometry to ensure laminar flow and representative residence time. [2] |

| S/N Dependence on Field | S/N ∝ B₀^1.5 [3] | S/N ∝ B₀^1.5 (inherently lower due to lower B₀) [3] | The primary driver for the sensitivity gap between high-field and benchtop systems. [3] [20] |

| Injected Sample Conc. (SEC-NMR) | ~1-3 g/L [3] | Requires optimization for lower sensitivity; similar concentration ranges used but with custom hardware/processing. [3] | SEC separation integrity limits maximum injectable concentration, challenging benchtop NMR sensitivity. [3] |

Experimental Protocols

Protocol: Characterizing Residence Time Distribution (RTD) in an NMR Flow Cell

Objective: To experimentally determine the flow profile and mixing behavior within a flow cell using NMR spectroscopy. [2]

Materials:

- NMR spectrometer (high-field or benchtop) with a flow probe.

- HPLC or syringe pump.

- Six-way injection valve.

- Miscible tracer substances (e.g., ethanol, acetone, methanol, each at 10 wt% in H₂O). [2]

- The flow cell and by-pass system to be characterized.

Method:

- Setup: Connect the by-pass system with the flow cell to the pump and the injection valve. Mount the flow cell in the NMR spectrometer.

- Flow Condition: Set the volume flow rate to a typical value for your application (e.g., 1-2 mL/min). [2]

- Tracer Injection: Using the six-way valve, inject a short, sharp pulse (or a step-change) of a tracer substance as close as possible to the flow cell inlet.

- Data Acquisition: Immediately after injection, start a rapid, consecutive series of ¹H NMR spectra acquisition to monitor the effluent from the flow cell.

- Repetition: Repeat the pulse-train injection with different tracer substances to confirm reproducibility and observe any substance-dependent effects. [2]

- Data Analysis: Plot the intensity of a characteristic signal from the tracer against time. This provides the experimental RTD curve. An ideal plug-flow reactor would show a sharp, symmetrical peak. Tailing or broadening indicates back-mixing or channelling. [2]

Protocol: Optimizing a Benchtop SEC-NMR Hyphenation

Objective: To achieve the highest possible sensitivity for on-line chemical composition detection after SEC separation on a benchtop NMR spectrometer. [3]

Materials:

- Benchtop NMR spectrometer (e.g., 62 MHz).

- SEC system with appropriate columns.

- Protonated SEC-grade solvent (e.g., CHCl₃, THF).

- Custom-designed flow cell for the benchtop NMR.

- Polymer standards (e.g., PS, PMMA) for testing.

Method:

- Flow Cell Design: Design a flow cell that maximizes the filling factor within the most homogeneous region of the benchtop magnet. This often requires a smaller diameter and/or length compared to high-field cells. [2] [3]

- Solvent Suppression: Implement a pulse program with effective solvent suppression (e.g., using frequency-selective pulses) to mitigate the large signal from the protonated mobile phase. [3]

- Chromatographic Optimization: Adjust SEC parameters (injection concentration, volume, flow rate) to balance separation quality with the highest possible analyte concentration entering the NMR flow cell.

- Data Acquisition and Processing: Run the SEC-NMR experiment. Use a continuous-flow acquisition mode. Process the data using a custom script (e.g., in MATLAB) to generate a 2D plot (retention time vs. chemical shift) and extract chemical composition as a function of molar mass. [3]

Workflow and System Diagrams

Workflow for EC-/Flow-NMR Cell Design

Benchtop NMR Hyphenation System

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Advanced NMR Flow and Electrochemistry Applications

| Item | Function / Application | Key Design Consideration |

|---|---|---|

| Custom Flow Cells | Housing the sample during on-line NMR measurements in by-pass or hyphenated systems (e.g., SEC-NMR, process monitoring). | Geometry (inlet/outlet, length) is critical to minimize residence time distribution (RTD) and ensure laminar flow in the active volume, especially for benchtop NMR. [2] [3] |

| Electrochemical Cell Components | Enabling in-operando NMR studies of batteries or electrolysis. Includes non-magnetic electrodes (e.g., thin Cu foils) and sealed cell housings. | Electrode orientation (parallel to B₁ field) and minimization of metal content are essential to reduce B₀ and B₁ field distortions and eddy currents. [21] |

| Deuterated Solvents | Providing a signal for the field-frequency lock system in high-field NMR. | Essential for high-resolution, long-term stability. For cost-sensitive hyphenated techniques (e.g., SEC-NMR), protonated solvents with suppression sequences are often used instead. [3] |

| NMR Tracers (e.g., D₂O, Methanol, Ethanol) | Used in pulse- or step-tracer experiments to characterize the residence time distribution and flow profile within a flow cell. [2] | Must be fully miscible with the solvent system and possess a distinct NMR signal for easy monitoring. |

| Spectral Reference Compounds | Chemical shift calibration. Common examples include TMS or DSS. Alternatively, the solvent signal can be used (e.g., cal command in TopSpin). [18] |

Should be inert and provide a sharp, well-defined resonance signal in a region that does not interfere with the analytes of interest. |

Advanced Applications: From Automated Reaction Optimization to Photochemical Studies

Integrating Benchtop NMR with Self-Optimizing Flow Reactor Systems

Technical Support Center

Troubleshooting Guides

Flow System and Hardware Issues

Problem: Flow cell clogging or precipitation in the transfer lines.

- Question: My reaction mixture is precipitating and clogging the flow cell or transfer lines. What can I do?

- Answer: Heterogeneous mixtures can cause clogging and spectral line broadening [23]. To mitigate this:

- Introduce a Diluent Stream: Add a third pump after the reactor to dilute the mixture with a compatible solvent before it enters the NMR flow cell. This reduces concentration and can prevent precipitation [14].

- Optimize Solvent System: Adjust the reaction solvent or mixture to improve solubility of reactants and products.

- Use a Glass Flow Cell: Consider switching to a dedicated glass flow cell with a wider internal diameter (e.g., 4 mm) instead of standard PTFE tubing to reduce the risk of blockages [23].

Problem: Poor or unstable NMR magnetic field lock.

- Question: The system won't lock, or the lock is unstable, leading to poor spectral quality.

- Answer: Benchtop NMR systems like the Spinsolve do not require deuterated solvents for locking [14]. If you are using a system that does, or are experiencing field instability:

- Check Shim Values: Load a standard set of starting shim values. On Bruker systems, you can type

rshand select "LASTBEST" to retrieve a reliable starting point [19]. - Perform Shimming: Execute a topshim procedure. For best results, use the "convcomp" (convection compensation) option if your sample is not spinning [19].

- Verify Hardware: Ensure the system's field drift compensation is active. Some systems may require periodic field updates [19].

- Check Shim Values: Load a standard set of starting shim values. On Bruker systems, you can type

Problem: Sample will not eject from the magnet.

- Question: I've commanded the system to eject, but the sample is stuck. What should I do?

- Answer:

- NEVER attempt to extract a sample by reaching into the magnet with any object, as this can cause severe damage [24].

- First, check if the issue is software-related. If you don't hear a click or change in airflow when ejecting, try restarting the communication software. On some systems, typing

su acqprocin a command shell can restart the acquisition process [24] [25]. - If you hear an audible change but the sample doesn't eject, use the manual eject button located on the magnet stand [24].

- If these steps fail, the sample or spinner may be physically stuck. Notify your facility manager or technical support immediately [24].

NMR Data Acquisition Issues

Problem: Autogain failure or ADC overflow error.

- Question: I receive an "Autogain Failure" or "ADC Overflow" error when starting an acquisition. How can I fix this?

- Answer: This error occurs when the NMR signal is too strong for the instrument's receiver [24].

- Reduce Pulse Width (pw): Decrease the pulse width parameter, for example, by typing

pw=pw/2. This reduces the amount of magnetization tipped into the XY-plane [24]. - Reduce Transmitter Power (tpwr): If the pulse width is already very low (~1 µs), reduce the transmitter power by 6 dB (

tpwr=tpwr-6) [24]. - Lower Sample Concentration: For future experiments, consider using a lower concentration of your analyte [24].

- Reduce Pulse Width (pw): Decrease the pulse width parameter, for example, by typing

Problem: Poor signal-to-noise or weak sensitivity for X-nuclei.

- Question: My signal for nuclei like ¹³C or ³¹P is very weak. How can I improve it?

- Answer:

- Optimize Hardware Tuning: For X-nuclei with large chemical shift ranges, ensure the probe is correctly tuned and matched for your specific nucleus of interest. The X-Pulse system, for example, allows for manual tuning to maximize sensitivity [26].

- Set Correct Spectral Parameters: Ensure the spectral width (SW) and transmitter offset (O1P) are set correctly to cover the relevant chemical shift range. An incorrect offset can lead to poor excitation and reduced signal [19].

- Increase Scans: Acquire more scans to improve the signal-to-noise ratio, though this will increase experiment time.

Software and Automation Control Issues

Problem: The automation software (e.g., IconNMR, LabView) is not responding to the hardware.

- Question: My software shows "Inactive" status and won't run experiments.

- Answer: This typically indicates a loss of communication between the computer and the spectrometer console [24] [25].

- Restart Acquisition Process: Open a system shell or command line and type

su acqprocto restart the acquisition process. Follow any on-screen prompts [24] [25]. - Check Experiment Status: Ensure you are "joined" to an experiment in the software. The status should read "Idle" or "Acquiring," not "Inactive" [24].

- Reboot Software/Hardware: If the above fails, try restarting the Topspin software or performing a full console reboot.

- Restart Acquisition Process: Open a system shell or command line and type

Problem: The optimization algorithm is not converging or is exploring poorly.

- Question: My self-optimizing reactor is not efficiently finding the optimum conditions.

- Answer:

- Verify Steady-State: Ensure the system reaches a steady state before recording data for the algorithm. One method is to take consecutive NMR measurements until the conversion/yield stabilizes [14].

- Check Algorithm Parameters: Review the parameters of your Bayesian optimization algorithm. The trade-off between "exploration" (testing new areas) and "exploitation" (refining known good areas) is crucial. Initial large fluctuations are normal [14] [27].

- Incorporate Prior Data: Consider using a Multi-Task Bayesian Optimization (MTBO) algorithm that can leverage pre-existing reaction data to accelerate the optimization process, especially when dealing with similar substrates [27].

Frequently Asked Questions (FAQs)

Q1: Can I use non-deuterated solvents with a benchtop NMR for reaction monitoring? A1: Yes, one of the key advantages of benchtop NMR systems like Spinsolve is that they do not require deuterated solvents for a lock system, allowing you to use protonated solvents and monitor reactions under realistic conditions [14] [28].

Q2: What kind of information can I get from in-line benchtop NMR beyond simple conversion? A2: Advanced structural characterization is possible. You can perform multi-nuclear experiments (¹⁹F, ¹³C), and even 2D NMR spectroscopy such as COSY, HSQC, and HMBC to identify intermediates, confirm products, and study reaction mechanisms on-the-fly [28] [26].

Q3: How do I calculate conversion and yield from my real-time NMR data? A3: NMR signals are quantitatively proportional to concentration. For the Knoevenagel condensation, conversion and yield were calculated using integrals of specific peaks and internal references [14]. * Reference Integral (R): A set of signals that do not change during the reaction (e.g., aromatic protons). * Reactant Integral (S1): A characteristic signal from the starting material. * Product Integral (S2): A characteristic signal from the product. Conversion and yield are then calculated using these integrals in predefined equations [14].

Q4: My sample is in a protonated solvent, and the solvent peak is overwhelming my analyte signals. What can I do? A4: Modern benchtop NMR systems are equipped with pulsed field gradients and shaped pulses as standard, which enable effective solvent suppression techniques. This allows you to suppress large solvent peaks and observe analyte signals even in protonated solvents like water or ethyl acetate [14] [26].

Experimental Protocols for Key Studies

Protocol 1: Self-Optimization of a Knoevenagel Condensation

This protocol details the setup for a self-optimizing flow reactor using Bayesian optimization and in-line NMR, as described in a 2025 application note [14].

1. Objective: Autonomously optimize the yield of 3-acetyl coumarin from salicylic aldehyde and ethyl acetoacetate.

2. Experimental Setup and Workflow: The workflow of the autonomous optimization loop is illustrated in the following diagram.

3. Key Research Reagent Solutions: Table: Essential reagents and materials for the Knoevenagel condensation optimization.

| Item | Function / Role | Example / Specification |

|---|---|---|

| Salicylic Aldehyde | Reactant (Aldehyde) | 104.5 mL (1 mol) in 1 L Ethyl Acetate [14] |

| Ethyl Acetoacetate | Reactant (Active Methylene) | 126.5 mL (1 mol) in 1 L Ethyl Acetate [14] |

| Piperidine | Basic Catalyst | 9.88 mL (10 mol%) [14] |

| Dilution Solvent | Prevents precipitation in flow cell | Acetone with 8.0 mL/L Dichloromethane [14] |

| Syringe Pumps | Precise reagent delivery | SyrDos or equivalent [14] |

| Microreactor | Provides controlled reaction environment | Ehrfeld MMRS [14] |

| Benchtop NMR | Real-time, in-line analysis | Spinsolve 80 ULTRA with qNMR module [14] |

4. NMR Acquisition Parameters: Table: Example NMR method for monitoring the Knoevenagel condensation.

| Parameter | Setting |

|---|---|

| Nucleus | ¹H |

| Pulse Sequence | 1D EXTENDED+ |

| Number of Scans | 4 |

| Acquisition Time | 6.55 s |

| Repetition Time | 15 s |

| Pulse Angle | 90° |

5. Data Analysis and Yield Calculation: Identify and integrate the following peaks in the ¹H NMR spectrum:

- Reference (R): Aromatic protons (6.6 - 8.10 ppm). Number of protons constant.

- Reactant, S1 (blue): Aldehyde proton of salicylaldehyde (9.90 - 10.20 ppm).

- Product, S2 (red): Olefinic proton of 3-acetyl coumarin (8.46 - 8.71 ppm).

Conversion is calculated as: ( \text{Conversion} = \frac{I{S1}}{I{S1} + I_{S2}} \times 100\% )

Yield is calculated as: ( \text{Yield} = \frac{I{S2}}{I{S1} + I_{S2}} \times 100\% ) [14]

Protocol 2: Real-Time Kinetic Monitoring of Imine Formation

This protocol is for a fundamental kinetic study, demonstrating the core capability of in-line NMR [28].

1. Objective: Monitor the kinetics of the condensation between benzaldehyde and benzylamine to form N-benzylidenbenzylamine.

2. Experimental Setup:

- Reactant Solutions: 1 M solutions of both benzaldehyde and benzylamine in MeOH (or CH₃CN) [28].

- Flow System: Use a simple setup with a 3-way mixer connected directly to PTFE tubing (1.5 mm ID) that passes through the NMR spectrometer, acting as the reactor [28].

- Procedure: Pump the solutions at a 1:1 volumetric ratio. Systematically decrease the total flow rate to increase the residence time in the reactor before the mixture enters the NMR flow cell. Acquire a spectrum at each flow rate.

3. Data Analysis:

- Monitor the disappearance of the benzaldehyde aldehyde proton at 9.4 ppm and the appearance of the imine proton at 7.9 ppm [28].

- Plot the concentration (from integral values) of the starting material and product against residence time.

- The reaction is known to follow second-order kinetics, which can be confirmed by fitting the concentration-time data [28].

The Scientist's Toolkit: Key Research Reagent Solutions

Table: Essential reagents, materials, and software for building and operating a self-optimizing NMR-flow reactor system.

| Category | Item | Function / Role | Key Considerations |

|---|---|---|---|

| Reactor Hardware | Syringe Pumps | Precise delivery of reactants [14] [28]. | Programmability for feedback control is essential. |

| Micromixer | Ensures rapid and complete mixing of reagent streams [28]. | Low dead volume. | |

| Tubing Reactor | PTFE capillary where the reaction occurs [28]. | ID and length determine residence time and pressure. | |

| Flow Cell | NMR-compatible cell holding sample in the RF coil [23]. | Glass with expanded ID or PTFE with guide tube [23]. | |

| Analytical Instrument | Benchtop NMR | Provides real-time, quantitative structural data [14] [28]. | No cryogens, high homogeneity, software control API. |

| Software & Control | Automation Software | Controls hardware, recipes, and data acquisition (e.g., LabVision, LabView) [14] [28]. | Modular, configurable, and able to interface with multiple devices. |

| Optimization Algorithm | Decision-making engine (e.g., Bayesian Optimization) [14] [27]. | Multi-task learning (MTBO) can leverage historical data [27]. | |

| Research Reagents | Deuterated Solvents | Not required for benchtop NMR locking [14] [28]. | Reduces cost and allows realistic conditions. |

| Dilution Solvent | Prevents clogging by diluting the reactor output [14]. | Must be miscible and not interfere with reaction or NMR. |

Real-Time Reaction Monitoring and Kinetic Analysis in Flow Cells

Troubleshooting Guide: Common Flow NMR Issues

This section addresses specific technical problems you might encounter during real-time reaction monitoring in flow NMR systems, with practical solutions to ensure data quality and instrument performance.

Q1: The system fails to lock, or the lock is unstable. What should I check?

- Verify Deuterated Solvent: Ensure your reaction mixture contains a sufficient amount of deuterated solvent for the lock system to function. For weakly locking solvents like CDCl₃, you may need to temporarily increase the lock power and gain to find the signal [24].

- Check and Adjust Lock Parameters: If the lock signal is off-resonance, manually adjust the Z0 parameter. If the signal is not symmetrical, adjust the lock phase via the BSMS control window [10] [18]. A 180-degree phase error will show the lock signal reaching a minimum first.

- Inspect Shim Settings: Poorly adjusted shims can prevent locking. Start by loading a standard set of shim values (e.g., using the

rtsorrshcommand in your NMR software) [24] [19].

Q2: After shimming, the spectral resolution remains poor. How can I improve it?

- Sample Quality: Check for issues like air bubbles, insoluble substances, or the use of a poor-quality NMR tube, all of which can cause poor shimming [10].

- Advanced Shimming Commands: Use the

topshim convcompcommand to compensate for convection currents, especially in non-viscous solvents. For higher-order shimming, you can specify the maximum order (e.g.,topshim ordmax=7) [19] [18]. - Manual Shim Optimization: If automated shimming fails, manually optimize the X, Y, XZ, and YZ shims. After adjusting each, re-optimize Z before proceeding to the next [10].

Q3: What does "ADC Overflow" mean, and how do I resolve it?

This error occurs when the NMR signal is too strong for the analog-to-digital converter (ADC), often due to high concentration or incorrect receiver gain [24] [10].

- Reduce Pulse Width (pw): Halve the pulse width parameter (e.g.,

pw=pw/2). Avoid reducing it below 1 microsecond [24]. - Adjust Transmitter Power (tpwr): If the problem persists, reduce the transmitter power by 6 dB (e.g.,

tpwr=tpwr-6) [24]. - Manually Set Receiver Gain (RG): If automatic gain adjustment (rga) sets the value too high, manually set RG to a value in the low hundreds to prevent overflow [10].

Q4: My sample is stuck in the flow system or magnet. What actions should I take?

- NEVER reach into the magnet with any object [24].

- Use Manual Eject: For sample changers, use the manual EJECT button on the instrument stand. If a tube is physically stuck in a SampleMail system, you may need to carefully remove the NMR tube from the spinner and unlock the mechanical switch [24] [10].

- Broken Tube in Magnet: If an NMR tube breaks inside the magnet, do not attempt to remove it yourself. Label the instrument as out of order and contact facility staff immediately to prevent probe damage [25].

Q5: Communication between the computer and console is lost. How can I reset it?

If the acquisition status shows "Inactive" or the instrument does not respond to commands:

- Restart the communication process by typing

su acqprocin a command shell [24] [25]. - If that fails, try

iiorii restartin the command line to reinitialize the interface [19] [18].

Quantitative Flow Effects and Data Correction

In flow NMR, the movement of the sample affects signal intensity. The following table summarizes key acquisition parameters and their influence on the signal, which is crucial for accurate kinetic analysis [29].

Table 1: Flow NMR Acquisition Parameters and Their Impact on Quantification

| Parameter | Effect on Signal | Consideration for Kinetic Analysis |

|---|---|---|

| Flow Rate | Higher flow rates reduce signal intensity due to shorter residence time in the detection coil. | A balance must be struck between temporal resolution and signal-to-noise ratio (SNR). |

| Relaxation Delay (D1) | Insufficient D1 leads to signal saturation because nuclei do not fully recover between scans. | For quantitative analysis, D1 should be ≥5 times the longitudinal relaxation time (T₁) of the slowest-relaxing nucleus. |

| Acquisition Time | Governs the temporal resolution of the experiment. | Short acquisition times increase temporal resolution but may decrease SNR and spectral resolution. |

Correction for Flow-Induced Signal Loss: The observed signal intensity in flow (S_flow) is reduced compared to a static sample (S_static). The signal can be corrected using the flow rate and the longitudinal relaxation time (T₁) of the nucleus [29]:

- S_static / S_flow ≈ 1 + (1 / (T₁ * (1/t - 1/τ))) Where t is the time constant for flow (inversely proportional to flow rate) and τ is the time constant for recovery (related to T₁ and D1). Ensuring a sufficient relaxation delay (D1) is the most practical way to minimize this quantification error.

Experimental Protocol: Automated Optimization of a Knoevenagel Condensation

This detailed methodology is adapted from a real-world application using a benchtop NMR system coupled with a flow reactor and Bayesian optimization algorithm [14].

Reagent and Solution Preparation

- Feed 1: Dissolve 104.5 mL (1 mol) of salicylaldehyde and 9.88 mL (10 mol%) of piperidine (catalyst) in ethyl acetate to make a final volume of 1 L.

- Feed 2: Dissolve 126.5 mL (1 mol) of ethyl acetoacetate in ethyl acetate to make a final volume of 1 L.

- Dilution Solvent: Dissolve 8.0 mL (125 mmol) of dichloromethane in acetone to make a final volume of 1 L. Function: Prevents product precipitation and dilutes the mixture for NMR analysis [14].

Flow Reactor and NMR Setup

- Reactor System: Use a modular microreactor system (e.g., Ehrfeld MMRS). Combine Feed 1 and Feed 2 in a micromixer and pass through a temperature-controlled capillary reactor.

- NMR Integration: Direct the output stream to a benchtop NMR spectrometer (e.g., Magritek Spinsolve Ultra) equipped with a flow cell. Use the "external control" mode to allow automation software to trigger NMR measurements.

- Automation & Analysis: Connect the NMR to process control software (e.g., HiTec Zang LabManager and LabVision). This software triggers NMR acquisitions, receives quantitative results, and executes the optimization algorithm [14].

NMR Acquisition Parameters for Quantitative Monitoring

- Pulse Sequence: 1D EXTENDED+ protocol (effectively a standard 1D proton experiment with solvent suppression).

- Scans (NS): 4

- Acquisition Time: 6.55 s

- Relaxation Delay (D1): 15 s

- Pulse Angle: 90°

- These settings are optimized for rapid, quantitative data collection in flow [14].

Quantitative Analysis and Feedback Loop

- Steady-State Check: For each set of reaction conditions (flow rates), take consecutive NMR measurements until three in a row show no significant change in conversion/yield, indicating a steady state has been reached.

- Yield Calculation:

- Define integrals:

- Reference (R): Aromatic region (6.6 - 8.10 ppm). Function: The number of aromatic protons (4) remains constant, serving as an internal standard [14].

- Aldehyde (S1): Signal from salicylaldehyde (9.90 - 10.20 ppm).

- Product (S2): Olefinic proton from 3-acetyl coumarin (8.46 - 8.71 ppm).

- Apply formulas:

- Define integrals:

- Optimization: The measured yield is fed to a Bayesian optimization algorithm, which calculates new parameters (e.g., flow rates of Feed 1 and Feed 2) for the next experiment, creating a closed feedback loop [14].

Automated Reaction Optimization Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials