LC-SPE-NMR: Revolutionizing Natural Product and Pharmaceutical Analysis with Drastic Deuterated Solvent Reduction

This article explores the transformative role of Liquid Chromatography-Solid Phase Extraction-Nuclear Magnetic Resonance (LC-SPE-NMR) as a powerful hyphenated technique that significantly reduces the reliance on expensive deuterated solvents in analytical...

LC-SPE-NMR: Revolutionizing Natural Product and Pharmaceutical Analysis with Drastic Deuterated Solvent Reduction

Abstract

This article explores the transformative role of Liquid Chromatography-Solid Phase Extraction-Nuclear Magnetic Resonance (LC-SPE-NMR) as a powerful hyphenated technique that significantly reduces the reliance on expensive deuterated solvents in analytical workflows. Tailored for researchers and drug development professionals, we cover the foundational principles of LC-SPE-NMR, detail its methodology for efficient analyte trapping and solvent exchange, and provide practical troubleshooting guidance. The discussion extends to a comparative analysis with other hyphenated techniques, validating its critical advantages in cost-efficiency, sensitivity, and application in characterizing complex mixtures like natural products and pharmaceutical impurities, ultimately outlining its future impact on biomedical research.

The High Cost of Clarity: Why Deuterated Solvents Challenge Traditional LC-NMR

Troubleshooting Guides

Q1: Why does NMR spectroscopy have inherently low sensitivity compared to techniques like UV-Vis?

The low sensitivity of NMR stems from the very small energy difference between nuclear spin states, resulting in an extremely small population excess in the lower energy state at thermal equilibrium [1].

- Inherently Small Population Difference: The population ratio between the lower (α) and upper (β) nuclear spin states is approximately 1.000064. For a million spins, there are only about 32 more in the α state than the β state. This tiny population excess is what generates the detectable NMR signal. In contrast, UV-Vis spectroscopy has a population ratio of approximately 1x10^42, meaning essentially all molecules are in the ground state, leading to a much larger signal [1].

- Dependence on Gyromagnetic Ratio and Field Strength: The signal-to-noise ratio (S/N) in NMR is proportional to the gyromagnetic ratio (γ) of the nucleus and the external magnetic field strength (B₀). The relationship is often expressed as S/N ∝ γ⁵/²B₀³/² [2]. This is why insensitive nuclei like ¹³C are more challenging to detect than ¹H, and why higher-field magnets are used to improve sensitivity.

Table 1: Quantitative Comparison of NMR and UV-Vis Sensitivity

| Feature | NMR Spectroscopy | UV-Vis Spectroscopy |

|---|---|---|

| Population Ratio (Ground/Excited) | ~1.000064 [1] | ~1x10^42 [1] |

| Typical Population Excess | 32 per million spins [1] | ~1,000,000 per million spins [1] |

| Energy Transition | Nuclear spin states [2] | Electronic states [1] |

Q2: My solvent peaks are overwhelming my analyte signals. What are the primary suppression methods and when should I use them?

Solvent suppression is critical in bio-molecular NMR and metabolomics where aqueous solutions are common. The choice of method depends on your sample and the information you need [3].

- Presaturation (PreSat): This is the simplest method, involving a weak, continuous radiofrequency (rf) field applied at the solvent resonance frequency during the recycle delay. It is very effective but can partially saturate signals close to the solvent peak and is susceptible to saturation transfer to exchangeable protons (e.g., NH), especially at higher pH [3].

- Pulse Field Gradient Methods (e.g., WET, WATERGATE): These methods use magnetic field gradients to dephase solvent magnetization. WET is excellent for suppressing multiple solvent peaks simultaneously and is robust and easy to implement [4]. WATERGATE is highly effective and independent of lineshape, providing superior suppression without affecting exchanging protons [3].

- 1D NOESY-presat: This popular method in metabolomics combines a recovery delay with presaturation of the water resonance. It often provides an improved baseline and solvent suppression compared to simple presaturation, though newer gradient methods can be superior [3].

Table 2: Comparison of Common Solvent Suppression Techniques

| Method | Principle | Best Use Cases | Key Limitations |

|---|---|---|---|

| Presaturation | Continuous weak RF irradiation during delay [3] | Simple, quick experiments; non-exchangeable protons of interest [3] | Saturates nearby signals; affects exchangeable protons (NH, OH) [3] |

| WET | Combination of selective pulses and pulsed field gradients [4] | Suppressing multiple solvent peaks (e.g., DMF) [4] | Requires good shimming; may suppress very close solute peaks [3] |

| WATERGATE | Bipolar gradient pulses to dephase solvent coherence [3] | High-quality suppression; samples with exchangeable protons [3] | Suppresses signals very close to the water resonance [3] |

| 1D NOESY-presat | Presaturation combined with NOE mixing scheme [3] | Metabolomics studies where legacy spectral databases are used [3] | Can be less effective than newer gradient-based methods [3] |

Q3: How can I improve the signal-to-noise ratio and resolution of my spectra?

Optimizing S/N and resolution is a multi-faceted process involving both sample preparation and instrument operation.

- Ensure Proper Sample Preparation:

- Optimize Instrument Setup:

- Shim the magnet meticulously: Good shimming is paramount for high resolution and effective solvent suppression. The process involves adjusting the currents in shim coils to maximize the homogeneity of the magnetic field (B₀) across your sample. This can be done automatically (e.g.,

topshim) or manually by adjusting Z, Z², X, Y, etc., while observing the lock level rise [4] [6]. - Calibrate pulse widths: An incorrectly calibrated 90° pulse will reduce signal intensity. The 90° pulse is typically calibrated by finding the 180° pulse length (which gives a null or inverted signal) and dividing it by two [4].

- Use an appropriate receiver gain (RG): Set the RG as high as possible without causing ADC overflow errors [7].

- Shim the magnet meticulously: Good shimming is paramount for high resolution and effective solvent suppression. The process involves adjusting the currents in shim coils to maximize the homogeneity of the magnetic field (B₀) across your sample. This can be done automatically (e.g.,

Q4: I am using LC-SPE-NMR. How does this technique specifically address solvent interference and sensitivity?

LC-SPE-NMR is a major advancement that directly tackles the core limitations stated in your thesis title by fundamentally changing how the analyte is presented to the NMR spectrometer [8].

- Deuterated Solvent Reduction: The technique uses non-deuterated, standard HPLC-grade solvents for the chromatographic separation. The analyte is trapped on an SPE cartridge and then eluted with a small, pure volume of deuterated solvent (e.g., ~300 µL of acetonitrile-d₃). This drastically reduces the consumption of expensive deuterated solvents and minimizes the residual solvent signal that needs to be suppressed [8].

- Sensitivity Enhancement via Analyte Focusing: The entire analyte from a potentially broad HPLC peak is trapped and focused into a very small volume on the SPE cartridge. When eluted, the entire sample is delivered to the NMR flow cell in a volume close to the detection volume of the probe. This eliminates the dilution that occurs in conventional LC-NMR, leading to a higher effective concentration and improved S/N [8].

- Multiple Trapping: A key feature for sensitivity is the ability to make multiple HPLC injections and trap the same analyte repeatedly on a single SPE cartridge. This pre-concentrates the analyte, substantially increasing the amount of material available for NMR analysis and enabling the acquisition of 2D NMR spectra on minor mixture components [8].

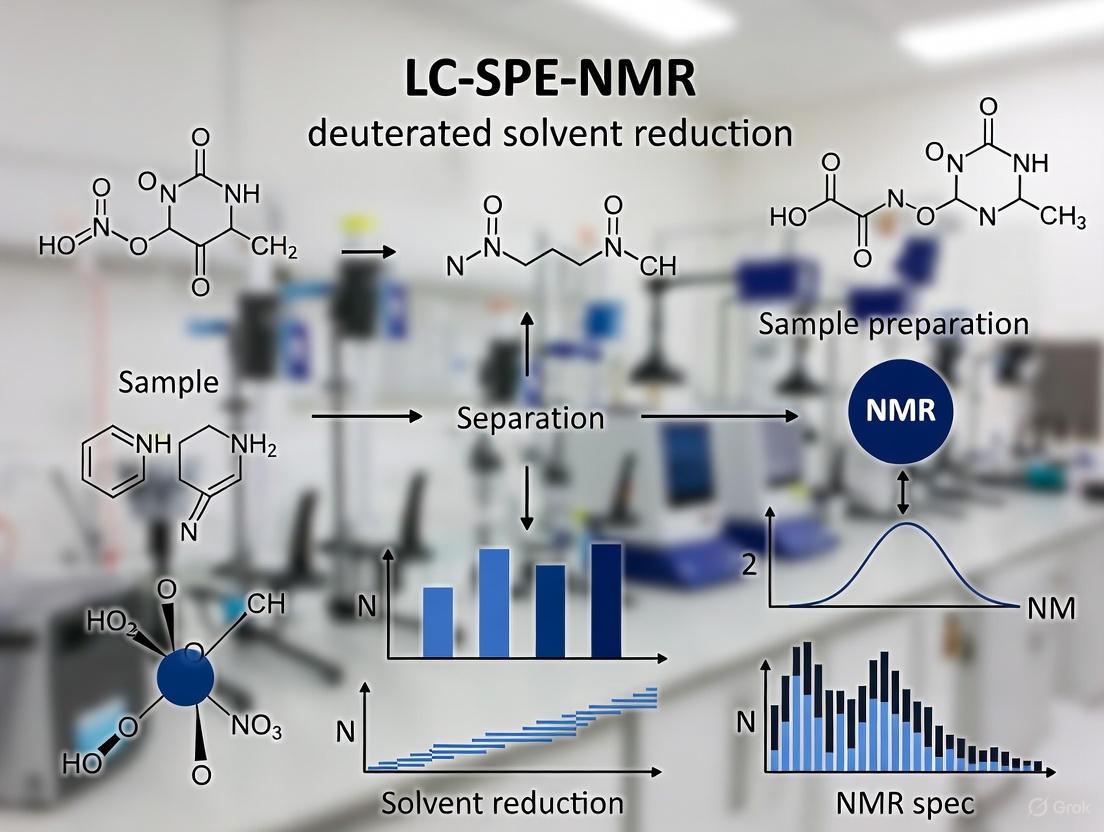

The following diagram illustrates the workflow of the LC-SPE-NMR technique, highlighting how it decouples the separation from the NMR analysis to overcome key limitations [8].

Experimental Protocols

Detailed Methodology: Implementing WET Solvent Suppression

The WET sequence is an effective method for suppressing multiple solvent peaks. The following steps outline how to set it up on a modern spectrometer running TopSpin [4].

Initial Setup and Shimming:

- Prepare your sample and insert it into the spectrometer.

- Lock and shim the sample to achieve optimal magnetic field homogeneity. Good shimming is critical for effective suppression [4].

- Acquire a standard ¹H spectrum to identify the solvent peaks you wish to suppress.

Define Suppression Regions:

- With the ¹H spectrum on the screen, go to the

Acquiremenu, selectOptions, and thenSetup Selective 1D Expts. - Click

Define Regions. Using the integration module, carefully select narrow regions around the center of each solvent peak you want to suppress. Avoid selecting wide regions to prevent suppressing your analyte signals. - Click

Save Region as...and selectSave regions to 'reg'. Then clickSave and Return[4].

- With the ¹H spectrum on the screen, go to the

Create the WET Dataset:

- Back in the

1D Selective Experiment Setupwindow, clickCreate Datasets. - Select

Mult. Solvent Suppr./WET. Enter the number of scans (NS, often 16 is sufficient) and a new experiment number. - A summary window will appear; click

Cancelto proceed with parameter adjustments [4].

- Back in the

Parameter Adjustment and Execution:

- Type

re [expno]to read the parameters of the new WET experiment. - Perform

atmato automatically tune and match the probe for both ¹H and ¹³C (WET suppresses ¹³C satellite peaks). - Increase the relaxation delay (

d1) to 6-10 seconds to ensure full recovery of your analyte magnetization, as WET uses 90° excitation pulses. - Type

rgato set the receiver gain, and thenzgto start the experiment [4].

- Type

Detailed Methodology: The LC-SPE-NMR Experiment

This protocol describes the general workflow for an HPLC-SPE-NMR experiment, which is central to research on deuterated solvent reduction [8].

Chromatographic Separation:

- Perform reversed-phase HPLC separation using standard, non-deuterated solvents (e.g., H₂O and acetonitrile).

- A post-column makeup pump is used to add at least a twofold volume of pure water to the eluate. This reduces the eluting power of the mobile phase, ensuring analytes are retained on the subsequent SPE cartridge [8].

Peak Trapping:

- As chromatographic peaks elute (triggered by UV or MS detection), the flow is directed to individual SPE cartridges (e.g., 2x10 mm or 1x10 mm).

- The analytes are adsorbed onto the SPE material while the diluted mobile phase passes through to waste [8].

Cartridge Processing:

- The SPE cartridges are dried with a stream of pressurized nitrogen gas to remove residual water and solvent.

- The trapped analytes are then eluted from the SPE cartridge using a small, pure volume of a suitable deuterated solvent (e.g., acetonitrile-d₃, typically ~300 µL) directly into the NMR flow cell [8].

NMR Acquisition:

- Once the focused analyte is in the NMR probe, standard 1D or 2D NMR experiments are acquired.

- Due to the analyte focusing and use of pure deuterated solvent, solvent suppression is often minimal or unnecessary, and sensitivity is significantly enhanced. For trace components, multiple trappings of the same peak from repeated HPLC injections can be performed to pre-concentrate the analyte [8].

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Advanced NMR Experiments

| Item | Function | Application Notes |

|---|---|---|

| Deuterated Solvents (D₂O, CDCl₃, ACN-d₃) | Provides a lock signal for the spectrometer; defines chemical shift reference [5]. | ACN-d₃ is often preferred in LC-SPE-NMR for its elution strength and low viscosity [8]. |

| SPE Cartridges (e.g., 2x10 mm) | Solid-phase extraction material for trapping HPLC-separated analytes [8]. | Reversed-phase sorption mechanism; choice of phase is critical for trapping efficiency [8]. |

| Internal Standards (TMS, DSS) | Chemical shift reference compound [5]. | TMS for organic solvents; DSS for aqueous solutions [5]. |

| High-Quality NMR Tubes (5 mm) | Holds the sample within the magnetic field [5]. | Use tubes rated for high magnetic fields (≥500 MHz); imperfections degrade resolution [7] [5]. |

| Shigemi Tubes | Matches magnetic susceptibility of specific solvents to limit the active sample volume [2]. | Maximizes signal-to-noise for mass-limited samples by concentrating spins in the detection region [2]. |

A significant economic challenge in modern analytical laboratories, particularly those utilizing LC-NMR and LC-SPE-NMR platforms, is the prohibitive cost of deuterated mobile phases. These solvents are essential for NMR detection as they reduce overwhelming solvent signals that would otherwise obscure analyte signals [9]. However, the routine use of fully deuterated mobile phases is often financially unsustainable, with a single critical run using deuterated acetonitrile costing approximately $100 [9]. This technical support center provides practical solutions and methodologies for researchers seeking to reduce deuterated solvent consumption without compromising analytical capabilities.

Cost Analysis: Deuterated Solvents vs. Traditional Mobile Phases

Table 1: Cost Comparison of HPLC Mobile Phase Components

| Solvent Type | Approximate Cost | Key Application in LC-NMR | Economic Consideration |

|---|---|---|---|

| Deuterated Acetonitrile (CD₃CN) | >$1 per mL [9] | Organic modifier in fully deuterated mobile phases | Cost-prohibitive for routine analysis; used sparingly |

| Deuterated Methanol (CD₃OD) | >$1 per mL (comparable to CD₃CN) | Organic modifier in fully deuterated mobile phases | Similar cost constraints to CD₃CN |

| Deuterated Water (D₂O) | <$0.50 per mL [9] | Aqueous component in mobile phases | Relatively inexpensive; often the only deuterated component in mixed phases |

| Standard HPLC-grade Acetonitrile | Minimal cost relative to deuterated versions | Organic modifier in standard HPLC | Cost-effective but generates strong interfering signals in NMR |

| Standard HPLC-grade Methanol | Minimal cost relative to deuterated versions | Organic modifier in standard HPLC | Cost-effective but generates strong interfering signals in NMR |

Research Reagent Solutions for Cost-Effective Analysis

Table 2: Essential Materials for LC-SPE-NMR Solvent Reduction

| Item / Reagent | Function in Experiment | Role in Cost Reduction |

|---|---|---|

| SPE Cartridges (DVB-type polymers, RP-C18) [10] | Traps and concentrates analytes post-LC separation; enables solvent exchange | Eliminates need for deuterated mobile phases during LC separation |

| Deuterated NMR Solvents (CD₃OD, CD₃CN) [10] | Elutes analytes from SPE cartridges into NMR flow cell | Reduces volume required from ~mL/min flow to <1 mL total per analysis [10] |

| Microcoil NMR Probes [9] | NMR detection with small active volumes (as low as 1.5 μL) | Enables use of highly concentrated samples in minimal deuterated solvent |

| Capillary HPLC System [10] | Chromatographic separation with reduced flow rates | Minimizes total solvent consumption throughout separation process |

| Post-column makeup pump [10] | Adds water to promote analyte retention on SPE cartridges | Facilitates efficient trapping without deuterated solvents in mobile phase |

Experimental Protocols for Deuterated Solvent Reduction

Protocol 1: Standard LC-SPE-NMR Workflow for Solvent Reduction

Purpose: To eliminate deuterated solvents from the LC mobile phase while maintaining NMR compatibility through post-separation solvent exchange.

Materials Required:

- HPLC system with UV or MS detector

- SPE unit with appropriate cartridge (typically DVB-polymer or RP-C18)

- Makeup pump with supply of H₂O

- Deuterated NMR solvent (CD₃OD or CD₃CN)

- NMR spectrometer with flow probe

Procedure:

- HPLC Separation: Perform chromatographic separation using standard (non-deuterated) mobile phases to eliminate deuterated solvent costs during separation [10].

Analyte Trapping: After UV or MS detection, divert analyte peaks to SPE cartridges. Use a makeup flow of H₂O (1-2 mL/min) to promote analyte retention on the SPE stationary phase [10].

Solvent Exchange: Wash trapped analytes with D₂O or H₂O to remove residual non-deuterated HPLC mobile phase [10] [11].

Analyte Elution: Transfer analytes to the NMR flow cell by back-flushing the SPE cartridge with a small volume (<1 mL) of appropriate deuterated solvent (CD₃OD or CD₃CN) [10].

NMR Analysis: Acquire NMR data with the analyte now dissolved in a pure, well-defined deuterated solvent.

Protocol 2: Multiple Trapping for Sensitivity Enhancement

Purpose: To concentrate analytes from multiple HPLC runs for improved NMR sensitivity without increasing deuterated solvent consumption.

Materials Required:

- LC-SPE-NMR system capable of automated multiple injections

- SPE cartridges with high trapping capacity (e.g., GP-phase)

Procedure:

- Initial Trapping: Perform first HPLC separation and trap target analyte on SPE cartridge as described in Protocol 1.

Repeat Injections: Make additional sequential injections, trapping the same analyte peak on the same SPE cartridge [10].

Capacity Monitoring: Monitor trapping efficiency; some stationary phases can retain >100 μg of analyte through multiple trappings [10].

Consolidated Elution: After sufficient analyte accumulation, elute with deuterated solvent directly into NMR flow cell.

Advanced NMR: Use the concentrated sample to acquire heteronuclear NMR experiments (e.g., HSQC, HMBC) overnight [10].

Technical Support Center

Troubleshooting Guides

Table 3: LC-SPE-NMR Troubleshooting for Solvent Reduction Methods

| Problem | Potential Causes | Solutions |

|---|---|---|

| Poor analyte recovery from SPE | Incorrect SPE stationary phase; Inadequate makeup flow; Suboptimal elution solvent | Test different SPE phases (SAX, SCX for polar compounds) [10]; Optimize H₂O makeup flow rate [10]; Ensure deuterated solvent has sufficient elutropic power [10] |

| Inadequate NMR sensitivity | Insufficient analyte concentration; Excessive dilution in NMR flow cell; Probe limitations | Use multiple trapping to concentrate analyte [10]; Employ microcoil probes with small active volumes [9]; Consider cryoprobes for sensitivity enhancement [9] |

| Chromatographic peak broadening in SPE-NMR | Large elution volume; Poor focusing during transfer; Excessive tubing volume | Optimize SPE elution for narrow band formation [10]; Minimize tubing between SPE and NMR cell; Ensure elution volume matches NMR flow cell volume [10] |

| System compatibility issues | Communication errors between modules; Pressure fluctuations; Mobile phase incompatibility | Verify control software integration [10]; Check for leaks or blockages [11]; Ensure all solvents are miscible and compatible [11] |

Frequently Asked Questions (FAQs)

Q1: What is the primary economic benefit of implementing LC-SPE-NMR versus traditional LC-NMR? The primary economic benefit is the dramatic reduction in deuterated solvent consumption. While traditional LC-NMR requires continuous flow of deuterated mobile phases throughout chromatography, LC-SPE-NMR uses deuterated solvents only for the final elution step, reducing consumption to less than 1 mL per analyte [10]. This represents potentially >90% savings in deuterated solvent costs.

Q2: Can I completely eliminate deuterated solvents from my LC-NMR workflow? While complete elimination is challenging due to the fundamental requirements of NMR spectroscopy, LC-SPE-NMR significantly minimizes consumption. The technique allows you to use standard, non-deuterated mobile phases for the chromatographic separation, reserving small, precise volumes of deuterated solvents only for the final NMR analysis step [10].

Q3: What are the key considerations when selecting SPE cartridges for solvent reduction methods? The selection depends on your analyte characteristics. DVB-type polymers and RP-C18 phases work for most applications [10]. For polar or charged analytes like alkaloids or organic acids, consider specialized phases such as SAX (strong anion exchange), SCX (strong cation exchange), or porous carbon materials [10]. Multiple trapping efficiency varies significantly between phases, so empirical testing is recommended.

Q4: How does the multiple trapping technique improve both economics and data quality? Multiple trapping concentrates analyte from several chromatographic runs onto a single SPE cartridge, allowing you to accumulate sufficient material for advanced NMR experiments (such as 2D spectra) without increasing deuterated solvent volume [10]. This improves sensitivity and data quality while maintaining low solvent consumption, making sophisticated structural elucidation more economically feasible.

Q5: What alternative NMR technologies can help reduce operational costs? Microcoil NMR probes with active volumes as low as 1.5 μL enable analysis of highly concentrated samples in minimal deuterated solvent [9]. Additionally, cryogenically cooled probes (cryoprobes) can provide 2-4 fold sensitivity improvements, potentially reducing analysis time or required sample amounts [9].

Workflow Visualization

Troubleshooting Guides

FAQ: Addressing Common Solvent Suppression Issues

Q: Why is my solvent suppression inefficient, leading to poor analyte visibility?

A: Inefficient suppression is often due to magnetic field inhomogeneity or an incorrect suppression frequency. In a highly homogeneous magnetic field, all solvent nuclei have identical resonance frequencies and can be efficiently suppressed when excited at the correct frequency [12]. First, ensure proper shimming has been performed. The final B0 deviation should be below 1 Hz [7]. Second, verify that the suppression sequence is calibrated and targeted at the exact resonance frequency of the solvent peak.

Q: What causes poor magnetic field homogeneity (shimming) in my flowing system?

A: Poor shimming can result from several factors [7]:

- Incorrect Sample Properties: Ensure your sample volume is sufficient and that the solution is homogeneous. The presence of air bubbles or suspended solid particles will distort the magnetic field, causing broad lines and poor shimming.

- System Issues: For high-temperature experiments, ensure the sample has reached full thermal equilibrium before shimming. Fluctuations in air flow can also destabilize the field.

Q: I see an "ADC overflow" error during my experiment. What should I do?

A: An ADC overflow error is typically caused by the receiver gain (RG) being set too high [7]. This can result in poor quality spectra or a complete failure to collect data.

- Immediate Action: Type "ii restart" in your console to reset the hardware after the error occurs.

- Prevention: Manually set the RG to a value in the low hundreds, even if the automatic tuning ("rga") suggests a higher value. Always monitor the first scan of an experiment to ensure no error occurs.

Q: How can I handle samples dissolved in protonated solvents without extensive sample preparation?

A: Using pulsed solvent suppression methods, like the WET sequence, is the key. This technique uses selective frequency excitation to attenuate the large solvent signals before the NMR signal is acquired [12]. This avoids the tedious workup required for solvent exchange, allowing for rapid analysis of samples directly from a synthesis process.

Q: Why is my NMR tube difficult to shim, or does it not fit the spinner correctly?

A: This is likely an issue with NMR tube quality and specifications [7] [13].

- Tube Quality: Low-quality or "high-throughput" NMR tubes have greater variation in outer diameter, which can cause spinner fitment problems and are typically more difficult to shim.

- Solution: Use high-frequency NMR tubes (for spectrometers >=500 MHz) from reputable suppliers. For a tube that is slightly too loose, a temporary fix is to wrap a thin strip of Scotch tape around the tube where the spinner holds it.

Experimental Protocol: WET Solvent Suppression for Aqueous Samples

This protocol details the acquisition of a 1H NMR spectrum for a dilute analyte in a protonated solvent, using water as an example.

1. Principle The WET (Water Suppression Enhanced through T1 effects) sequence employs a series of selective pulses and pulsed magnetic field gradients to selectively saturate the intense solvent signal while minimally affecting the signals of interest from the analyte [12].

2. Materials and Sample Preparation

- Prepare your sample dissolved in a protonated solvent (e.g., neat water).

- While deuterated solvents are standard for locking, this method is designed for protonated solvents on systems with an external hardware lock [12].

- Ensure the sample is homogeneous and free of suspended particles to prevent magnetic field inhomogeneity [13].

3. Instrument Setup

- Calibrate Pulses: Ensure the selective pulses for the solvent suppression sequence are properly calibrated for the solvent's resonance frequency.

- Set Acquisition Parameters:

- Pulsed Field Gradients: Configure the gradient strengths and durations as defined by the WET sequence.

- Receiver Gain (RG): Set manually to a value in the low hundreds to prevent ADC overflow [7].

- Scans (NS): 64 scans or as required for sufficient signal-to-noise.

- Relaxation Delay (D1): 10 seconds to allow for magnetization recovery [12].

4. Data Acquisition and Processing

- Execute the WET solvent suppression sequence.

- After acquisition, process the FID with exponential line broadening (e.g., 0.3 Hz) and apply a Fourier transform.

- The solvent peak should be significantly attenuated (e.g., by a factor of 1000), revealing the analyte signals [12].

The Scientist's Toolkit: Research Reagent Solutions

The following table details key materials and reagents essential for successful solvent suppression experiments, particularly within LC-SPE-NMR workflows focused on deuterated solvent reduction.

| Item | Function & Relevance to Solvent Suppression |

|---|---|

| Deuterated Solvents (e.g., DMSO-d6, CDCl3) | Provides a deuterium signal for the magnetic field lock, which is crucial for maintaining field stability and frequency reproducibility during long or complex experiments [13]. |

| WET Solvent Suppression Sequence | A pulse sequence that uses selective excitation and pulsed field gradients to attenuate large solvent signals. It is the key to analyzing samples in protonated solvents without extensive preparation [12]. |

| High-Quality NMR Tubes | Tubes with tight tolerances (e.g., Precision grade) ensure consistent spinning and are easier to shim, which is a prerequisite for effective solvent suppression [7] [13]. |

| Internal Standard (e.g., TMS, DSS) | Provides a reference peak for chemical shift calibration (δ = 0 ppm). The concentration must be very low to avoid dynamic range issues that can distort the baseline [13]. |

| Benchtop NMR with External Lock | Systems like the Spinsolve ULTRA with an external hardware lock enable the analysis of samples in non-deuterated solvents, as they do not rely on the sample's deuterium signal for field stabilization [12]. |

Workflow Visualization

Solvent Suppression Workflow

LC-SPE-NMR Solvent Reduction

Technical Support Center

This support center provides targeted troubleshooting guides and FAQs to assist researchers in overcoming common challenges in LC-SPE-NMR workflows, with a special focus on methods that reduce deuterated solvent consumption.

Troubleshooting Guides

Table 1: Common LC-SPE-NMR Issues and Solutions

| Problem Area | Specific Issue | Possible Cause | Recommended Solution |

|---|---|---|---|

| NMR Sensitivity | Poor Signal-to-Noise Ratio | Inadequate analyte concentration [9]. | Use LC-SPE to concentrate samples; employ cryoprobes or microcoil probes [9]. |

| Solvent Management | High cost of deuterated solvents [9]. | Using fully deuterated mobile phases. | Use LC-SPE for post-column analyte trapping; elute with minimal volume of deuterated solvent [9] [14]. |

| Chromatography | Retention time shift in LC-NMR | Deuterium isotope effect when using D2O in the mobile phase [9]. | Account for retention time shifts in method development; consider LC-SPE to decouple LC from NMR. |

| System Operation | ADC overflow error on NMR spectrometer |

Receiver gain (RG) set too high [7]. | Set RG to a low hundreds value; type ii restart to reset hardware after error [7]. |

| System Operation | Poor shimming results | Inhomogeneous sample, air bubbles, or poor-quality NMR tube [7]. | Ensure sufficient sample volume and deuterated solvent; use rsh to read a good prior shim file and rerun topshim [7]. |

Frequently Asked Questions (FAQs)

Q1: Why is LC-SPE-NMR considered a major evolution from direct LC-NMR? LC-SPE-NMR addresses the primary limitation of direct on-flow or stop-flow LC-NMR: the inherent low sensitivity of NMR. By trapping chromatographic peaks on solid-phase extraction cartridges, analytes can be concentrated and then eluted with a small, defined volume of deuterated solvent. This process significantly enhances analyte concentration for NMR detection and drastically reduces the consumption of expensive deuterated solvents [9] [14].

Q2: My NMR experiment failed with an automation error on the Bruker spectrometer. What are the first steps I should take?

Stop the automation in IconNMR. In the TopSpin command line, type ii to reinitialize the system. Run this command a few times until no error messages appear. You can then try to manually tune and match the probe (atmm). If successful, restart the automation in IconNMR. If errors persist, restarting TopSpin may be necessary [15].

Q3: Can LC-MS data alone replace the need for LC-NMR or LC-SPE-NMR in structural elucidation? No. LC-MS and LC-NMR provide complementary data. While LC-MS is highly sensitive and provides molecular weight and elemental composition, it often cannot distinguish between isobaric compounds or positional isomers. NMR is essential for providing definitive structural information, including atomic connectivity and stereochemistry. The techniques are synergistic, with LC-MS often used for initial screening and dereplication, and LC-SPE-NMR for complete structure determination [9] [14].

Q4: What is the single biggest factor limiting the sensitivity of online LC-NMR, and how does LC-SPE-NMR mitigate it? The key limiting factor is the low sensitivity of the NMR experiment itself, which requires relatively high concentrations of analyte and long acquisition times. This stems from the small energy difference between nuclear spin states [9]. LC-SPE-NMR mitigates this by trapping and concentrating HPLC peaks, effectively increasing the analyte concentration presented to the NMR probe, which improves the signal-to-noise ratio and reduces the required acquisition time [9] [14].

Experimental Protocols

Detailed Methodology: LC-SPE-NMR for Natural Product Identification

The following protocol, adapted from research on plant secondary metabolites, outlines a standard workflow for analyzing complex plant extracts using LC-SPE-NMR with optimized deuterated solvent use [14].

1. Sample Preparation

- Extraction: Homogenize plant material (e.g., 50-300 mg) and extract with an appropriate solvent. Methanol or methanol-deuterium oxide mixtures are often effective for broad metabolite coverage [16].

- Filtration: Centrifuge the extract and filter the supernatant through a 0.45 µm membrane filter prior to LC injection to prevent column clogging.

2. Liquid Chromatography Separation

- Column: Use a suitable reversed-phase C18 column.

- Mobile Phase: Employ a binary solvent system. To reduce costs, the aqueous phase can be deuterium oxide (D2O), while the organic phase (e.g., acetonitrile or methanol) is used in its protonated form [9].

- Gradient: Optimize a linear gradient for compound separation. The effluent is split post-column, with a minor portion directed to the mass spectrometer and the majority to the SPE unit.

3. Mass Spectrometry Detection

- The split flow is analyzed by MS using electrospray ionization (ESI).

- MS data acquired in real-time is used to make decisions on which chromatographic peaks to trap based on their mass and fragmentation pattern.

4. Solid-Phase Extraction (SPE) Trapping

- Peak Triggering: The system is programmed to trigger a trapping event based on UV or MS signal thresholds.

- Trapping: The HPLC peak is diluted with water to reduce eluting strength and loaded onto a conditioned SPE cartridge (e.g., Hysphere C18 cartridge). Hydrophilic compounds are adsorbed onto the sorbent.

- Drying: An inert gas stream (e.g., nitrogen) passes through the cartridge to remove the protonated solvents completely.

5. NMR Analysis

- Elution: The trapped analyte is eluted from the SPE cartridge directly into the NMR flow cell using a small, precise volume (e.g., 30-150 µL) of deuterated solvent (e.g., CD3OD or [D6]DMSO).

- Data Acquisition: Once the analyte is transferred, standard 1D and 2D NMR experiments (e.g., 1H, COSY, HSQC, HMBC) are performed. The use of cryoprobes or microcoil probes is recommended to maximize sensitivity with the low-volume, concentrated sample [9].

Workflow Visualization

LC-SPE-NMR Workflow

Research Reagent Solutions

Table 2: Essential Materials for LC-SPE-NMR Experiments

| Item | Function / Rationale |

|---|---|

| Deuterated Methanol (CD3OD) | Common elution solvent in LC-SPE-NMR; offers good solubility for a wide range of mid-polarity metabolites. Using it sparingly for final elution is key to cost reduction [9] [16]. |

| Deuterium Oxide (D2O) | Relatively inexpensive deuterated solvent often used as the aqueous component of the LC mobile phase to reduce solvent signal interference in NMR [9]. |

| C18 Reversed-Phase SPE Cartridges | The solid-phase medium used to trap, wash, and concentrate analytes of interest after LC separation, enabling the switch from protonated to deuterated solvents [14]. |

| Methanol (HPLC Grade) | Common protonated solvent for sample extraction and as the organic modifier in the LC mobile phase. 90% methanol with 10% CD3OD can be an effective extraction solvent for NMR [16]. |

| Cryoprobes / Microcoil NMR Probes | Sensitivity-enhanced NMR probes. Cryoprobes reduce electronic noise, while microcoil probes work efficiently with low-volume samples, both crucial for analyzing the low-quantity samples typical in LC-SPE-NMR [9]. |

The LC-SPE-NMR Workflow: A Practical Guide to Efficient Solvent Reduction

Troubleshooting Guide: Resolving Common Issues

Why is my chromatographic separation poor when I use non-deuterated solvents as a precursor to LC-NMR?

Poor separation can stem from various factors unrelated to your solvent choice. The table below outlines common symptoms, their causes, and solutions.

| Symptom | Potential Cause | Solution |

|---|---|---|

| Broad Peaks [17] | System not equilibrated; Injection solvent too strong; Column overload (volume or mass). | Equilibrate column with 10 volumes of mobile phase; Ensure injection solvent is same/weaker strength than mobile phase; Reduce injection volume or sample concentration [17]. |

| Tailing Peaks [17] | Column degradation (old, contaminated, or voided); Injection solvent too strong. | Replace guard cartridge or column; Wash contaminated column; Use a weaker injection solvent [17]. |

| Varying Retention Times [17] | System not equilibrated; Temperature fluctuations; Pump not mixing solvents properly. | Fully equilibrate column; Use a thermostatically controlled column oven; Check pump proportioning valve function [17]. |

| Extra Peaks [17] | Degraded sample; Contaminated solvents or column; "Ghost peaks" from gradient elution. | Inject a fresh sample; Use fresh, high-quality HPLC solvents; Replace guard cartridge; Wash the column [17]. |

How can I manage the strong solvent signal from non-deuterated solvents in NMR analysis?

The intense signal from protonated solvents can overwhelm the weaker signals from your analyte. The primary solution is to use a pulse sequence that suppresses solvent signals [18].

- Technology Used: The WET pulse suppression sequence is an effective method integrated into modern NMR software (e.g., JEOL's No-D NMR) [18].

- How It Works: This technique applies specific radiofrequency pulses to selectively excite and suppress the hydrogen signals from the solvent, allowing the much smaller analyte signals to be detected clearly.

- Consideration: A potential limitation is that analyte signals that overlap with the solvent peak may also be suppressed [18].

What should I do if my NMR system fails to "lock" without deuterated solvent?

Traditional NMR spectrometers use the deuterium signal from the solvent for a process called "field/frequency locking" to maintain magnetic field stability [19].

- Solution: Newer techniques like No-D NMR (No-Deuterium Proton NMR) bypass this requirement. Instead of locking on deuterium, the system performs proton gradient shimming using the strong signal from the protonated solvent itself to stabilize the magnetic field [18]. This makes deuterated solvents unnecessary for the locking process.

Frequently Asked Questions (FAQs)

Can I use any non-deuterated solvent for LC-SPE-NMR?

While you have more flexibility, the choice is not arbitrary. You should select solvents based on:

- Solubility: The solvent must fully dissolve your sample [19].

- Chromatographic Performance: It should provide good separation efficiency (e.g., sharp peaks) [17].

- NMR Signal Interference: The solvent's proton signals should not critically overlap with your analyte's key resonances. Careful solvent selection can minimize this issue [18].

- Compatibility with SPE: The solvent must be compatible with the solid-phase extraction process, which typically uses non-deuterated solvents before the analyte is eluted with a minimal volume of deuterated solvent for the final NMR step [20].

What are the main cost benefits of using non-deuterated solvents?

The primary benefit is a significant reduction in solvent expenses. Deuterated solvents like Acetonitrile-d₃ can cost over $1.00 per mL, whereas their protonated equivalents are orders of magnitude cheaper [9]. For the initial chromatographic separation and SPE trapping steps, which consume the bulk of the solvent, using standard HPLC-grade solvents leads to substantial cost savings without compromising the quality of the separation or the structural information obtained from NMR [20].

How does the LC-SPE-NMR workflow integrate with non-deuterated solvents?

This workflow is specifically designed to minimize the consumption of expensive deuterated solvents [20]. The process is visualized in the diagram below.

Diagram Title: LC-SPE-NMR Solvent Reduction Workflow

- Separation: The mixture is first separated using a standard LC system with non-deuterated solvents [20].

- Trapping: As peaks elute from the column, they are directed and adsorbed onto Solid-Phase Extraction (SPE) cartridges [20].

- Drying: The trapped analytes on the SPE cartridge are dried, typically with a stream of nitrogen gas, to evaporate the non-deuterated solvents [20].

- Elution: The purified analyte is then eluted from the SPE cartridge using a small, controlled volume of deuterated solvent directly into the NMR spectrometer for analysis [20].

Research Reagent Solutions

The table below lists key materials used in the LC-SPE-NMR workflow with non-deuterated solvents.

| Item | Function in the Experiment |

|---|---|

| HPLC-Grade Solvents (e.g., Acetonitrile, Methanol) [20] | The mobile phase for the initial liquid chromatography separation; chosen for their purity and optimal chromatographic performance. |

| Solid-Phase Extraction (SPE) Cartridges [20] | To trap, concentrate, and purify analyte peaks after LC separation, enabling the removal of non-deuterated solvents. |

| Deuterated Solvent (minimal volume) [20] | To elute the purified analyte from the SPE cartridge for the final NMR analysis, providing the deuterium signal for the lock system in standard NMR. |

| Inert Gas (N₂) [20] | To dry the SPE cartridges after trapping the analyte, ensuring complete removal of non-deuterated solvents before NMR elution. |

The following diagram illustrates the complete post-column analyte trapping and focusing process in LC-SPE-NMR.

Troubleshooting Guide

Common Problems and Solutions

| Problem | Possible Causes | Recommended Solutions |

|---|---|---|

| Low Analyte Recovery | • Eluent strength insufficient• Elution volume too small• Wrong sorbent chemistry | • Increase organic modifier percentage• Use stronger elution solvent• Increase elution volume in increments [21] |

| Poor Reproducibility | • Variable flow rates• Cartridge bed dried out pre-load• Wash solvent too strong | • Control flow to 1-2 mL/min [21]• Keep sorbent wet; re-equilibrate if dry [21]• Weaken wash solvent strength [21] |

| Unsatisfactory Cleanup | • Incorrect purification strategy• Poor solvent selection | • Retain analyte, wash impurities [21]• Re-optimize wash/elution conditions [21] |

| Slow/Variable Flow Rate | • Particulate clogging• High sample viscosity | • Filter/centrifuge sample pre-load [21]• Dilute sample to lower viscosity [21] |

| Failure to Trap Polar Compounds | • Reversed-phase sorption mechanism limitation | • Dilute HPLC eluate with water (2:1) [8]• Explore polar stationary phases [8] |

Frequently Asked Questions (FAQs)

Q1: Why is post-column dilution with water necessary before SPE trapping? Post-column dilution with water decreases the concentration of the organic modifier in the HPLC eluent, reducing its eluting power. This increases the affinity of analytes for the reversed-phase SPE stationary phase, ensuring they are retained on the cartridge instead of passing through to waste [8].

Q2: What is the purpose of drying the SPE cartridge with nitrogen gas before elution? Drying the cartridge with pressurized nitrogen gas removes residual water and the non-deuterated HPLC solvents [8]. This is a critical step to prevent contamination of the final NMR sample with protonated solvents, which would require strong solvent suppression and compromise spectral quality.

Q3: How does this step contribute to the overall sensitivity of LC-SPE-NMR? This step focuses the analyte. The analyte from a potentially broad HPLC peak is trapped and concentrated onto a small SPE cartridge (e.g., with a bed volume of ~8-30 µL) and then eluted with a minimal volume (e.g., <30 µL) of deuterated solvent. This "analyte focusing" results in a much higher sample concentration in the NMR flow cell compared to the original HPLC peak volume [8].

Q4: Can I increase the amount of analyte for NMR analysis? Yes, a key advantage of this method is "multiple trapping." The same analyte from repeated HPLC separations can be trapped onto the same SPE cartridge, significantly increasing the amount of material available for NMR analysis and allowing for the acquisition of more time-consuming 2D NMR experiments [8].

Q5: My very polar analyte is not being trapped. What can I do? The reversed-phase sorption mechanism used in most current HPLC-SPE-NMR setups has a serious limitation in trapping very polar compounds [8]. Potential solutions include optimizing the post-column dilution ratio or, in the future, exploring the use of polar stationary SPE phases, though this is an area requiring further development [8].

Research Reagent Solutions

Essential Materials for Post-Column Trapping

| Item | Function & Key Characteristics |

|---|---|

| SPE Cartridges | Small cartridges (e.g., 1x10 mm or 2x10 mm) with reversed-phase sorbent (e.g., C18) to trap and focus analytes [8]. |

| Deuterated Elution Solvents | High-purity solvents (e.g., Acetonitrile-d₃, Methanol-d₄, Chloroform-d) to quantitatively transfer analyte to NMR tube/probe with minimal signal interference [8] [19]. |

| Post-Column Pump | Delivers a precise flow of pure water to dilute the HPLC eluent, reducing its eluting power and enabling analyte retention on the SPE cartridge [8]. |

| Nitrogen Gas Supply | Provides pressurized gas for drying the SPE cartridges after trapping to remove residual protonated solvents [8]. |

| Automated SPE Interface | System that coordinates trapping triggered by UV/MS, cartridge drying, and elution with deuterated solvent into the NMR flow cell or tube [8]. |

Frequently Asked Questions (FAQs)

Q1: Why is efficient drying of the SPE cartridge critical before solvent exchange? Efficient drying with pressurized nitrogen gas is essential to remove all traces of the non-deuterated HPLC mobile phase (e.g., H₂O, acetonitrile, methanol). Residual protons from these solvents would cause significant interference in the subsequent NMR analysis, leading to large unwanted peaks that require solvent suppression and can obscure analyte signals [10] [8].

Q2: What are the consequences of incomplete solvent exchange on my NMR spectrum? Incomplete exchange results in a mixed solvent system within the NMR flow cell. This leads to multiple, strong solvent peaks, complicated solvent suppression routines, and a increased risk of signal overlap with your analyte of interest. A successful exchange to a pure deuterated solvent provides a well-defined and reproducible NMR environment, simplifying spectral interpretation [10] [8].

Q3: My analyte is not eluting efficiently from the SPE cartridge with the deuterated solvent. What could be wrong? The elution power of the deuterated solvent might be insufficient. Acetonitrile-d₃ is a general-purpose, non-viscous solvent that often provides good results. For more non-polar compounds, chloroform-d can be effective, while methanol-d₄ is better for polar compounds. The strong coordinating properties of DMSO-d₆ can make it difficult to elute analytes as a sharp band, which is why it is less commonly used in online SPE-NMR workflows [8].

Q4: I suspect water contamination in my final sample. How can I confirm and fix this? Water peaks are a common issue. If you observe a large peak for water in your NMR spectrum, it could originate from wet solvent or incomplete drying of the SPE cartridge. To prevent this, ensure your deuterated solvents are anhydrous and that the nitrogen drying step is thorough. NMR solvents can also collect water over time; adding an inert drying agent like molecular sieves to your solvent bottle can help [22] [8].

Q5: How does multiple trapping enhance sensitivity and reduce deuterated solvent use? Multiple trapping involves repeatedly injecting and concentrating the same analyte from successive HPLC runs onto a single SPE cartridge. This strategy accumulates microgram quantities of the analyte, allowing for the acquisition of 2D NMR experiments without overloading a single chromatographic run. Since the entire accumulated sample is eluted with a single, small volume (e.g., < 30 µL) of deuterated solvent, the technique maximizes the analyte concentration in the NMR flow cell while minimizing per-analysis solvent consumption [10] [8].

Troubleshooting Guide

| Problem | Possible Cause | Solution |

|---|---|---|

| Poor NMR signal-to-noise ratio after elution | • Analyte not fully transferred from SPE cartridge• Elution volume too large, diluting the analyte | • Optimize deuterated solvent elution strength [8]• Ensure cartridge size matches NMR cell volume for focused elution [8] |

| Large solvent peaks in NMR spectrum | • Incomplete drying of SPE cartridge• Use of non-deuterated solvent for elution | • Extend nitrogen drying time to remove all protonated solvent [8]• Use pure, high-quality deuterated solvents [19] |

| Analyte recovery is low | • Analyte is too polar for reversed-phase SPE material• Wrong deuterated solvent for elution | • Consider alternative SPE phases (SAX, SCX) for polar analytes [10]• Test different deuterated solvents (CD₃CN, CD₃OD) for optimal elution [8] |

| Broad or distorted peaks in NMR | • Poor magnetic field shimming due to improper sample• Sample is not homogeneous | • Ensure sample is fully dissolved and the cartridge is properly dried [7]• Check that the eluted sample forms a homogeneous solution in the flow cell [22] |

Research Reagent Solutions: Essential Materials

The following table details key reagents and materials essential for the efficient drying and solvent exchange process in LC-SPE-NMR.

| Item | Function in the Protocol |

|---|---|

| SPE Cartridges | The solid-phase medium that traps HPLC-separated analytes. Common types include reversed-phase (C-18, DVB polymer) for most applications, and ion-exchange (SAX, SCX) for charged/polar compounds [10] [8]. |

| Pressurized Nitrogen Gas | An inert gas stream used to dry the SPE cartridge thoroughly after trapping, removing all residual protonated HPLC solvent before elution with deuterated solvent [10] [8]. |

| Deuterated Acetonitrile (CD₃CN) | A preferred elution solvent due to its low viscosity, good eluting power for many compounds, and well-defined residual solvent peak at ~1.94 ppm [8] [19]. |

| Deuterated Methanol (CD₃OD) | A protic deuterated solvent used for eluting more polar compounds. Its residual proton peak is found at ~3.31 ppm [8] [19]. |

| Deuterated Chloroform (CDCl₃) | A standard NMR solvent suitable for eluting non-polar compounds from SPE cartridges. Its residual proton peak is a singlet at 7.26 ppm [8] [19]. |

| Deuterium Oxide (D₂O) | Used as the aqueous component in the HPLC mobile phase and sometimes as a post-column makeup fluid to promote analyte retention on the SPE cartridge [10] [9]. |

Experimental Workflow and Protocol

The following diagram illustrates the key steps for efficient drying and solvent exchange in the LC-SPE-NMR process.

Detailed Protocol for Optimized Solvent Exchange

SPE Cartridge Drying:

- After the target analyte is trapped on the SPE cartridge from the HPLC eluent, activate the nitrogen drying system.

- The drying time must be sufficient to ensure all traces of the protonated mobile phase (e.g., H₂O, CH₃CN, CH₃OH) are evaporated from the cartridge. Inadequate drying is a primary source of large contaminant peaks in the NMR spectrum [8].

Selection of Deuterated Solvent:

- Choose a deuterated solvent based on its elution strength for your analyte and its suitability for NMR. Acetonitrile-d₃ (CD₃CN) is highly recommended as a first choice due to its low viscosity and general effectiveness [8].

- Other common choices are methanol-d₄ (CD₃OD) for polar compounds and chloroform-d (CDCl₃) for non-polar compounds [8] [19].

Elution and Transfer:

- Use the minimal volume of deuterated solvent required to quantitatively elute the analyte from the SPE cartridge as a narrow band. This volume is typically designed to match the active volume of the NMR flow probe (e.g., 30-60 µL for a 30-60 µL flow cell) [10] [8].

- This "peak focusing" is the key to maximizing analyte concentration and sensitivity while conserving expensive deuterated solvent.

Deuterated Solvent Comparison

The table below provides a quantitative comparison of common deuterated solvents used in LC-SPE-NMR elution, highlighting key properties for selection.

| Solvent | Typical Residual ¹H Peak (ppm) | Boiling Point (°C) | Relative Cost | Best Use Case in SPE Elution |

|---|---|---|---|---|

| Acetonitrile-d₃ (CD₃CN) | 1.94 [19] | 82 [19] | Medium | General purpose; excellent for sharp elution bands due to low viscosity [8]. |

| Methanol-d₄ (CD₃OD) | 3.31 [19] | 65 [19] | Medium | Polar compounds that require a protic solvent for elution [8]. |

| Chloroform-d (CDCl₃) | 7.26 [19] | 61 [19] | Low | Non-polar organic compounds [8]. |

| Dimethyl Sulfoxide-d₆ (DMSO-d₆) | 2.50 [19] | 189 [19] | High | Problematic polar compounds; less ideal for online elution due to high viscosity [8] [19]. |

Troubleshooting Guide: Common Issues and Solutions

This guide addresses specific issues that can occur during the elution and data acquisition phase of an LC-SPE-NMR experiment, with a focus on maintaining data quality while minimizing deuterated solvent consumption.

Symptom 1: High Baseline Noise or Drift in the NMR Spectrum

| Symptom | Possible Cause | Solution |

|---|---|---|

| Erratic baseline noise [23] | Air bubble in the LC system or NMR flow cell. | Purge the entire system, including the LC pump and the NMR flow cell, with fresh, degassed mobile phase. |

| Regular, cyclic noise pattern in the baseline [24] [23] | Inconsistent pump operation causing fluctuations in mobile phase composition or flow rate. | Perform routine maintenance on pump check valves and seals. Verify that the deuterated solvent composition is consistent and correctly mixed. |

| Overall bad baseline with high noise [23] | General system contamination. | Perform a thorough system cleaning, flushing both the LC and NMR flow path with appropriate solvents. For UV detectors, a noisy baseline can also indicate a failing lamp or flow cell [23]. |

| Baseline drift during gradient elution [24] | Detector response to a major mobile phase component (e.g., formic acid absorbing strongly at low UV wavelengths). | Ensure the additive is present in both solvent A and B to maintain a consistent concentration, or use a detection wavelength where the additive does not absorb. |

Symptom 2: Poor Peak Shape or Anomalous Peaks in the NMR Spectrum

| Symptom | Possible Cause | Solution |

|---|---|---|

| Peak tailing [23] | - Column overloading- Contamination- Interactions with active sites on the trapping column | - Dilute the sample or reduce the injection volume.- Flush the SPE cartridge and analytical column with strong solvent.- Ensure the trapping chemistry is compatible with your analyte. |

| "Ghost peaks" (peaks not from the analyte) [24] [25] | Elution of highly retained impurities from the mobile phase or system. | Use high-purity, LC-MS grade solvents and additives. Run a blank gradient to identify and flush out impurities. In one case, changing the supplier of isopropanol immediately resolved the issue [24]. |

| Artifact peaks from contamination [25] | Leachables from system components (e.g., septa, tubing) contacting the sample or solvent. | Identify and replace the source of contamination. One study found artifact peaks originated from the sample vial septum [25]. |

| Broadened or split peaks [23] | - Incompatibility between sample solvent and initial mobile phase.- Excessive system volume. | - Dilute the sample in a solvent that matches the initial mobile phase composition.- Use shorter, narrower internal diameter (I.D.) tubing to connect the LC-SPE to the NMR flow cell to reduce post-column volume. |

Symptom 3: Reduced Sensitivity or Signal-to-Noise Ratio

| Symptom | Possible Cause | Solution |

|---|---|---|

| Low signal intensity across all peaks [23] | - Incorrect sample concentration or injection volume.- Analyte adsorption to active sites. | - Verify sample preparation steps and dilution calculations.- Condition the system with a few preliminary injections to passivate active sites. |

| Poor magnetic field homogeneity (line shape) | Inadequate shimming due to improper sample conditions or unstable lock signal. | Ensure the deuterated solvent used for elution is of high isotopic purity (≥99.8%) to provide a strong and stable lock signal for the spectrometer [19]. |

| Overwhelmed NOE effects or "Oversaturation" [26] | Use of overly intense RF saturation pulses during NMR experiments, which can smear out cross-relaxation information. | Optimize the amplitude (γB1/2π) of the saturation pulse. Start with weaker values (e.g., ~10 Hz) and increase only as needed to avoid broadening the signals of interest [26]. |

Frequently Asked Questions (FAQs)

Q1: What are the most critical factors for selecting a deuterated solvent for the final elution in LC-SPE-NMR? The key factors are solubility compatibility (the solvent must fully dissolve your target analyte from the SPE cartridge), chemical compatibility (the solvent should not cause unwanted proton exchange or chemical shifts), and deuterium purity. High isotopic purity (≥99.8%) is crucial for a stable field/frequency lock and for minimizing the large solvent peak that can interfere with your spectrum [19].

Q2: Why might I see unexpected "cross-peaks" in my NOE or SMT NMR spectra after elution? Unexpected cross-peaks can be artifacts from "spill-over" effects. This occurs when a long or intense selective saturation pulse unintentionally affects the signals of nearby protons, making them appear as if they are cross-relaxing [26]. To avoid this, ensure your saturation pulse parameters (power, duration, and frequency) are correctly calibrated for your specific sample and isolated peak.

Q3: How can I reduce deuterated solvent consumption in my LC-SPE-NMR workflow without compromising data quality? Optimizing the elution volume is essential. Use the minimum volume of deuterated solvent needed to quantitatively transfer the analyte from the SPE cartridge to the NMR flow cell. This can be determined experimentally during method development. Furthermore, using a solvent with a high boiling point (like DMSO-d₆) can be beneficial if you need to recover your sample, but it may be harder to remove from the system later [19].

Q4: The baseline in my NMR spectrum is unstable after elution. What LC-related issues should I investigate? This often points to mobile phase inconsistencies. Check that your pump is delivering a consistent flow and that your solvent composition is stable. A failing pump seal or a sticky check valve can cause composition fluctuations that manifest as baseline noise or drift in the NMR detector [24] [23]. Always use high-purity solvents and additives to minimize chemical baseline contributions.

Experimental Protocol: Optimizing the Elution-to-Acquisition Workflow

The following protocol is designed to ensure a robust transfer of the isolated analyte into the NMR flow cell for high-quality data acquisition.

Objective: To reliably elute a target compound from an SPE cartridge using a minimal volume of deuterated solvent and acquire a high-fidelity NMR spectrum.

Materials and Reagents:

- LC-SPE system with appropriate switching valves

- NMR spectrometer with a flow probe (flow cell)

- High-purity deuterated elution solvent (e.g., CD₃CN, CD₃OD, DMSO-d₆)

- Standard sample for system performance verification

Procedure:

- System Priming: Pre-condition the entire fluidic path from the SPE cartridge to the NMR flow cell with the selected deuterated elution solvent. This removes any residual protonated solvent and ensures a homogeneous environment for the analyte.

- Elution Trigger: Activate the method step that switches the valve to direct the flow of deuterated solvent through the SPE cartridge. The flow rate and elution volume should be optimized to ensure quantitative transfer of the analyte. A typical flow rate is 0.5 - 1.0 mL/min.

- Transfer to Flow Cell: The eluted band, now in deuterated solvent, is transferred directly into the NMR flow cell. The transfer tubing should be as short and narrow in I.D. as possible to minimize peak broadening [23].

- NMR Probe Tuning: Once the elution peak is detected as being within the flow cell (often via a UV signal), stop the flow. Manually or automatically tune and match the NMR probe to the sample/solvent combination.

- Magnetic Field Lock and Shimming: Engage the deuterium field-frequency lock using the signal from the deuterated solvent. Perform automated shimming (e.g., gradient shimming) to optimize the magnetic field homogeneity for the best possible spectral line shape.

- Data Acquisition: Begin the NMR experiment (e.g., 1D ( ^1H )) using parameters optimized for your sample. For NOE-based experiments, carefully calibrate saturation power and duration to avoid artifacts like "oversaturation" [26].

- System Cleanup: After acquisition, flush the system thoroughly with a protonated solvent (e.g., acetonitrile/water) to prepare for the next run and to conserve expensive deuterated solvents.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in LC-SPE-NMR | Key Consideration |

|---|---|---|

| Deuterated Elution Solvents (CD₃CN, CD₃OD, DMSO-d₆) [19] | Dissolves and transfers the analyte from the SPE cartridge to the NMR flow cell while providing a deuterium signal for the field-frequency lock. | Select based on analyte solubility and chemical compatibility. Higher deuterium purity (≥99.8%) provides a more stable lock and cleaner baseline [19]. |

| SPE Cartridges | Traps and concentrates the target compound from the LC mobile phase, allowing for solvent exchange to deuterated NMR solvent. | The stationary phase must be orthogonal to the LC column to ensure effective trapping and must be compatible with the deuterated elution solvent. |

| LC-MS Grade Solvents & Additives [24] [23] | Used in the initial LC separation and SPE trapping steps to minimize UV-absorbing or NMR-active impurities that cause ghost peaks or high baseline. | Essential for preventing contamination that can be concentrated on the SPE cartridge and eluted into the NMR, complicating spectral interpretation. |

| NMR Reference Compound (e.g., TMS) [27] | Provides a known internal standard (0 ppm) for precise chemical shift referencing in the final NMR spectrum. | Can be added in small quantities to the deuterated elution solvent if needed, though residual solvent peaks are often used as a secondary reference. |

LC-SPE-NMR Elution & Acquisition Workflow

The diagram below illustrates the core pathway and key decision points for transitioning a sample from the solid-phase extraction (SPE) cartridge to high-quality NMR data acquisition.

Troubleshooting Guides

HPLC Method Development for Impurity Profiling

Problem: Inadequate separation of impurities from the main drug substance. Separation is the foundation of reliable impurity profiling. Poor selectivity can lead to co-elution, making accurate quantification impossible.

- Diagnosis: Closely eluting peaks or peaks with shoulder(s) observed in the chromatogram; spectral purity analysis (PDA) indicates potential co-elution [28].

- Solution:

- Select Dissimilar Chromatographic Columns: Screen the impurity mixture on 4-5 reversed-phase columns with different selectivity (e.g., C18, phenyl, cyano). Use chemometric approaches or column characterization parameters to select the most orthogonal columns [29].

- Optimize Mobile Phase pH: Screen a pH range of 2–9 (within column stability limits) in combination with the selected columns. Model the retention time (tR) of each impurity as a function of pH to predict the pH that provides the maximum minimal resolution (Rsmin) between consecutive peaks [29].

- Reconsider Gradient Slope: If the overall Rsmin remains low after pH optimization, adapt the gradient's start and end conditions or the gradient time to spread the peaks over a wider retention window [29].

- Prevention: Follow a structured method development approach, sequentially optimizing the stationary phase, pH, organic modifier, and temperature based on their influence on selectivity [29].

Problem: Drifting retention times and peak shape issues. Retention time stability is critical for reproducible results and accurate peak identification.

- Diagnosis: Consistent drift in retention time across injections; poor peak symmetry (tailing or fronting) [30].

- Solution:

- Verify Buffer Capacity: Ensure the buffer concentration is sufficient (typically 10-100 mM, with 25 mM being common) to control pH effectively throughout the analysis. A salt solution without adequate buffering capacity at the desired pH will lead to instability [30].

- Check HPLC Instrumentation: Monitor system pressure for consistency. Check for pump malfunctions, faulty sealings, or issues with the solvent mixing device [30].

- Confirm Sample Stability: Some analytes, like omeprazole, are unstable under acidic conditions or when exposed to light or prolonged sonication. Ensure samples are stored in stable, buffered conditions and protected from light [30].

- Prevention: Regularly calibrate and maintain the HPLC system. Use a column oven for stable temperature control and always employ a buffer with adequate capacity at the target pH [30].

LC-SPE-NMR and Structural Elucidation

Problem: Inaccurate quantitative evaluation in ¹H NMR. Accurate integration is essential for determining compound purity, ratios in mixtures, and quantitative structure assessments.

- Diagnosis: Inconsistent integration values between proton environments; large errors (>3%) when comparing different proton types (e.g., aromatic CH to a methyl group) [31].

- Solution:

- Optimize Relaxation Delay: Set an adequate delay (5–10 seconds) between scans to avoid saturation effects, especially for small molecules with long T1 relaxation times [31].

- Ensure Proper Digital Resolution: Acquire the spectrum with enough data points to accurately define each peak. A resonance with a width of 0.5 Hz should be sampled every 0.25 Hz for <1% error [31].

- Account for Isotopic Satellites: ¹³C satellites can contribute 1.1% to a peak's total area. Use ¹³C decoupling or ensure satellites from intense peaks do not overlap with the signal being integrated [31].

- Correct the Baseline: Use NMR software routines to adjust for baseline slant or curvature before integration [31].

- Prevention: For high-accuracy quantitation (<1% error), routinely measure T1 relaxation times to calculate the optimal relaxation delay and ensure excellent signal-to-noise [31].

Problem: Difficulty identifying isomeric impurities or confirming stereochemistry with LC-MS. Mass spectrometry may not distinguish compounds with identical molecular weights but different structural arrangements.

- Diagnosis: LC-MS data shows a single mass for a peak, but other data suggests a mixture or unknown stereochemistry.

- Solution:

- Employ 2D NMR Techniques: After isolation via LC-SPE, use a suite of NMR experiments [32]:

- COSY: Identifies proton-proton coupling networks.

- HSQC/HMQC: Maps direct correlations between protons and their attached carbon atoms.

- HMBC: Detects long-range (2-3 bond) proton-carbon couplings, establishing connectivity.

- NOESY/ROESY: Provides spatial proximity information critical for determining 3D configuration and stereochemistry [32].

- Use Chiral NMR Techniques: Apply chiral solvating agents or shift reagents to resolve and assign chiral centers [32].

- Employ 2D NMR Techniques: After isolation via LC-SPE, use a suite of NMR experiments [32]:

- Prevention: Integrate NMR as an orthogonal technique to LC-MS in impurity profiling workflows, as it is uniquely sensitive to isomeric differences and spatial structure [32].

Frequently Asked Questions (FAQs)

1. How do I assess peak purity in HPLC, and why can't I rely on retention time alone? A photodiode array (PDA) detector is the most common tool for assessing peak purity. It measures UV absorbance across a peak and identifies spectral variations that may indicate co-elution. Software calculates metrics like purity angle and threshold, but these should never be used alone. Always manually review spectral overlays, especially at the peak edges, as co-elution can compromise quantification even when a peak appears well-resolved. For definitive assessment, LC-MS detects co-elution based on mass differences [28].

2. What are the key factors to consider when developing an impurity profiling method? The development follows a sequential optimization of factors based on their influence on selectivity [29]:

- Stationary Phase: Has the largest influence. Start by screening a set of dissimilar (orthogonal) columns.

- Mobile Phase pH: Critically affects the selectivity for ionizable compounds. Optimize next.

- Organic Modifier: The type (e.g., acetonitrile vs. methanol) and composition can be fine-tuned.

- Gradient and Temperature: These factors are optimized last for final method tuning.

3. My sample's impurity profile changes over time. What could be causing this? This is a common stability issue. Factors include [30]:

- Light Exposure: UV light can catalyze photodegradation reactions.

- Solution pH: The sample may be unstable at the storage pH. For example, omeprazole degrades in acid.

- Sonication: Extended sonication can provide enough energy to degrade compounds or promote reactions. To prevent this, store samples in amber vials, ensure the solution pH is stable, and minimize sonication time.

4. When is NMR superior to LC-MS for impurity identification? NMR is particularly powerful in these scenarios [32]:

- Isomeric Impurities: It can distinguish positional isomers, tautomers, and stereoisomers that have identical masses.

- Non-Ionizable Compounds: It detects compounds that do not ionize well and may be missed by MS.

- Full Structural Elucidation: It provides the complete molecular framework, including functional groups and relative stereochemistry, without the need for reference standards.

- Chiral Analysis: It can resolve and assign chiral centers.

5. How does buffer concentration affect my HPLC analysis? Buffer concentration plays a key role in method robustness [30]:

- Too Low (<10 mM): Can lead to peak shape problems (tailing) and retention time variability because the mobile phase pH is poorly controlled.

- Adequate (10-100 mM): Provides stable pH control, ensuring consistent ionization states, retention times, and peak shapes. 25 mM is a common starting point.

- Too High: May exceed the salt's solubility in the mobile phase (e.g., causing phosphate salts to precipitate with acetonitrile) and potentially reduce column lifespan.

Workflow and Relationship Diagrams

Diagram 1: Impurity Profiling Method Development Workflow

Diagram 2: LC-SPE-NMR for Impurity Identification

Research Reagent Solutions

This table lists key materials and their functions in developing robust impurity profiling methods.

| Reagent/Material | Function in Impurity Profiling |

|---|---|

| Dissimilar HPLC Columns (e.g., C18, Phenyl, Cyano) | Screening columns with different selectivities to maximize the chance of resolving all impurities from the main compound and from each other [29]. |

| Buffers (e.g., Phosphate, Formate, Acetate) | Control the pH of the mobile phase to manipulate the ionization and thus the retention of ionizable analytes, which is a primary factor affecting selectivity [29] [30]. |

| Deuterated Solvents (e.g., CD₃OD, D₂O, CDCl₃) | The NMR-active solvent for structure elucidation after LC-SPE isolation. Allows for locking and shimming the NMR magnet and does not produce interfering signals in the ¹H spectrum [32]. |

| Chiral Derivatizing Agents | Chemicals that react with chiral analytes to form diastereomers, which can then be separated by standard HPLC or analyzed by NMR to determine enantiomeric purity and absolute configuration [32]. |

| Solid Phase Extraction (SPE) Cartridges | Used in the LC-SPE interface to trap HPLC eluates, remove non-deuterated solvents, and concentrate the analyte for subsequent NMR analysis, significantly enhancing sensitivity [32]. |

Frequently Asked Questions

What is multi-trapping 2D-LC and what is its primary advantage? Multi-trapping two-dimensional liquid chromatography (2D-LC) is an advanced analytical technique where a sample is first separated in a first dimension (1D) column, after which specific analyte fractions are temporarily stored, or "trapped," on a secondary column. The primary advantage is the ability to perform multiple trapping cycles from successive HPLC runs, concentrating low-level analytes to significantly improve the signal-to-noise ratio for detection and quantification [33].

Which low-level impurities can be monitored with this technique? This technique is particularly suited for enriching and quantifying challenging low-level impurities in pharmaceutical development, including:

- Unknown impurities at sub-parts-per-million (ppm) levels [34].

- Co-eluting impurities that can lead to undesired summation above specification limits [34].

- Potential mutagenic impurities at ppm levels, even in poorly soluble substrates [33] [34].

What are the quantitative performance characteristics of multi-trapping 2D-LC? When properly configured, the technique demonstrates excellent quantitative performance. Studies show it can achieve a recovery rate of over 97.0% with a relative standard deviation (RSD) of lower than 3.0%, confirming its accuracy and precision for impurity analysis. The system also demonstrates linear enrichment for up to 20 trapping cycles [33] [34].

Troubleshooting Guides

Poor Recovery of Target Analytes

Problem: Inconsistent or low recovery of analytes from the trap column.

Solution:

- Verify Trap Column Sorbent: Ensure the trap column sorbent is compatible with your target analytes and the mobile phases used in both dimensions. The sorbent must efficiently trap and subsequently release the analytes [34].

- Check Online Dilution: For methods that use online dilution to ensure the 1D eluent is compatible with the trapping process, confirm the dilution ratio and mixing efficiency. Inadequate dilution can lead to poor trapping efficiency [34].

- Review Valve Switching Timing: Precise timing of the switching valves is critical to ensure the entire fraction of interest is transferred to the trap column and later to the 2D column for analysis. Even minor timing errors can cause significant analyte loss [34].

Inconsistent Enrichment Linearity Over Multiple Cycles

Problem: The increase in analyte signal is not linear with the number of trapping cycles.

Solution:

- Confirm System Stability: Before starting a multi-trapping sequence, ensure the 1D separation is highly reproducible. Any retention time drift in the 1D separation will result in the heart-cut window missing the target analyte in subsequent cycles [34].

- Inspect Trap Column Capacity: Verify that the mass of the analyte being loaded over multiple cycles does not exceed the binding capacity of the trap column. Overloading will lead to analyte breakthrough and loss [33].

- Validate Fluidics: Check for any leaks or inconsistencies in the pumping systems that could affect the transfer volume and consistency between cycles [34].

Experimental Performance Data

The following table summarizes the quantitative performance of multi-trapping 2D-LC as demonstrated in real-world pharmaceutical case studies [33] [34].

| Application / Analyte | Impurity Level | Number of Trapping Cycles | Recovery (%) | Precision (RSD) |

|---|---|---|---|---|

| Unknown impurities (material discoloration) | Sub-ppm | 10 | >97.0 | <3.0% |

| Co-eluting impurity | 0.05% (w/w) | Information not specified | >97.0 | <3.0% |

| Potential mutagenic impurity | 10 ppm | Information not specified | >97.0 | <3.0% |

| Standard test mixture (varied compounds) | Up to 0.15% (w/w) | 20 | >97.0 | <3.0% |

Detailed Experimental Protocol: Multi-Trapping 2D-LC for Impurity Enrichment

This protocol outlines the methodology for enriching low-level impurities using a heart-cutting trapping mode 2D-LC system, built from standard, GMP-ready instrument modules [34].

1. Instrument Configuration

- System: A 2D-LC system configured with an additional binary pump for the second dimension.

- Valves: Two 6-port/2-position switching valves are used to control the heart-cutting and trapping processes.

- Columns:

- 1D Column: A suitable fit-for-purpose column for the initial separation.

- Trap Column: A short column selected for its ability to focus and retain the target analytes.

- 2D Column: A suitable analytical column for the final separation of the enriched analytes.

- Detection: UV and/or Mass Spectrometry detectors after the 2D column [34].

2. Procedure

- Step 1: First Dimension Separation. The sample is injected and separated on the 1D column. The mobile phase is optimized for high-resolution separation of the complex mixture.

- Step 2: Heart-Cutting and Trapping. As the peak(s) of interest elute from the 1D column, the switching valve is activated to divert the fraction containing the analyte onto the trap column. The trap column captures and focuses the analyte while incompatible solvents are washed to waste. This step is repeated for multiple injections to accumulate the analyte.

- Step 3: Second Dimension Elution. After the desired number of trapping cycles, the switching valve reconfigures the flow path. The 2D pump delivers a strong mobile phase to elute the concentrated analyte from the trap column onto the 2D analytical column.

- Step 4: Second Dimension Separation and Detection. The analyte undergoes a final separation on the 2D column under optimized conditions and is then directed to the detector (UV or MS) for sensitive quantification [33] [34].

The Scientist's Toolkit: Research Reagent Solutions